1-5T/D Small Scale Palm Oil Refinery Machine in Durban

- Usage: Palm Oil, Palm Oil

- Type: Cold & Hot Pressing Machine

- Automatic Grade: Automatic, Automatic

- Production Capacity: 99%, 100%

- Model Number: HH-POM

1-5T/D Small Scale Palm Oil Refinery Machine in Durban Description

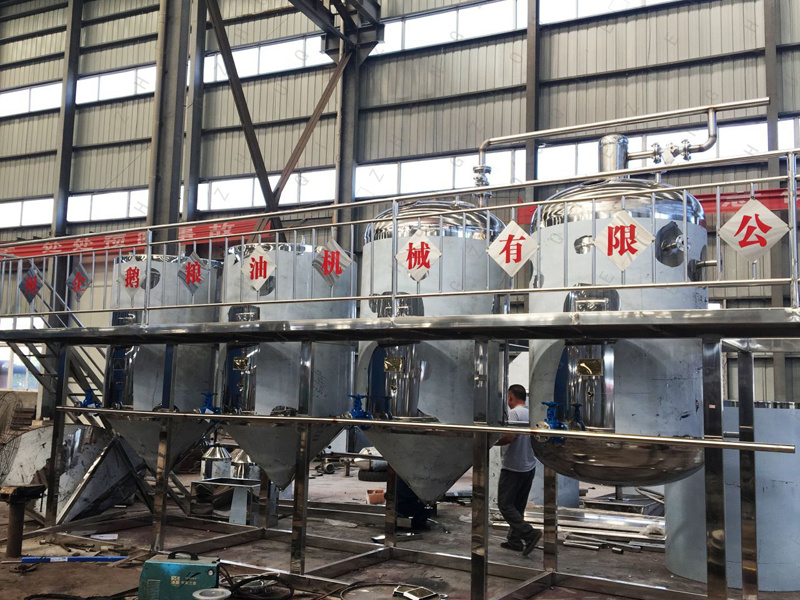

1-5T/D small scale palm oil refinery Machine

What is Small scale palm oil refining Machine ?

The crude oil obtained either from expellers or solvent extraction plant contains impurities, which must be removed to make the oil edible, more palatable and stable against rancidity upon storage. The process of removing these impurities is called refining.

What is Small scale palm oil refining Machine ?

1)chemical refining 2) physical refining 3)chemical-physical refining

Small scale palm oil refining Machine detail describle:

(1). Refining pot: used to P-acid de-gumming, alkali refining de-acid and water rinsing.

(2).De-color pot: used to remove off pigments, bleaching oils and grease de-hydrate. (3).De-odor pot: used to remove off oils odor, foreign smells (stainless made) Heat transfer oil stove: supply each device production needing heat energy, temperature reach above 280 ° C.

(4).Steam generator: produce the needing steam for de-odoring and distillation. (5).Vacuum pump: supply needing vacuum for dehydrate, de-color, de-odor. Vacuum degree can

reach above 755mmHg.

(6).Press filter: filter clay, filter out clear oil.

(7).Air compressor: blow dry bleached clay, blow empty the leftover oil in

Small scale palm oil refining Machine operation process:

Step 1.Degumming with water to remove the easily hydratable phospholipids and metals.

Step 2.Addition of a small amount of phosphoric or citric acid to convert the remaining non-hydralable phospholipids (Ca, Mg salts) into hydratable phospholipids.

Step 3.Neutralising of the free fatty acids with a slight excess of sodium hydroxide solution, followed by the washing out of soaps and hydrated phospholipids.

Step 4.Bleaching with natural or acid-activated clay minerals to adsorb colouring components and to decompose hydroperoxides.

Step 5.Deodorising to remove volatile components, mainly aldehydes and ketones, with low threshold values for detection by taste or smell. Deodorisation is essentially a steam distillation process carried out at low pressures (2-6 mbar) and elevated temperatures (180-220°C). What is Small scale palm oil refining Machine ?

Packaging & ShippingOur ServicesCompany Information

Workshop production capacity:

FAQ

The machine of sunflower oil refining line adapt to many materials,such as soybean,copra,cottonseed,sesame,corn germ,rice bran and all of vegetable oil materais,welcome you to visit our web,and send your detial enquiry!

Technical parameters of 1-5T/D Small Scale Palm Oil Refinery Machine in Durban

| Voltage | 380V |

| Power(W) | 85kw |

| Dimension(L*W*H) | according to the specification |

| Weight | 35ton, changed with the capacity |

| Certification | ISO9001,BV,CE |

| After-sales Service Provided | Engineers available to service Machine overseas |

| Capacity | 1T to 500T |

| Material of equipment | stainless steel and carbon steel |

| Raw material | all kins of oil seeds |

| including | machines,installation,tech consulting after sales |

| operattion | automatic and safe |

| type | Palm Oil Extraction Equipment |