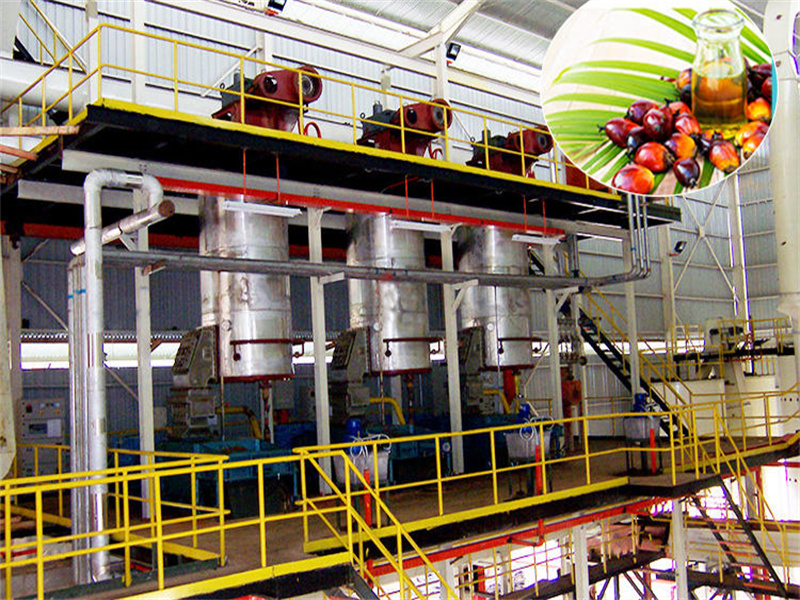

100Tpd Palm Kernel Oil Production Line Machine in Kenya

- Usage: all kinds vegetable seeds crude oil

- Type: palm oil refinery

- Automatic Grade: Automatic

- Production Capacity: 20-300TPD palm oil refinery

- Model Number: semi-continuous or full continuous Palm palm oil refinery

100Tpd Palm Kernel Oil Production Line Machine in Kenya Description

Qie Company

Company introduction

Zhengzhou Qi’e Grain & Oil Machine Co., Ltd is a large-sized joint-equity enterprise which is specialized in producing edible oil mechanical equipment and it is also a group enterprise integrating scientific research, manufacturing, sales as one.

Our company has set up Mechanical Design and Research institution, oil press machine department, large-sized complete oil equipment department, International trade department, production department. Our business involves in small-sized oil pressing series, Grain and oil engineering designing, equipment manufacturing and installing, project contracting, technical service, new product development, the intensive and deep processing for oil by-products etc.

Our Company has grown into Chinese grain and oil Machine production and export base with scientific management methods, we have been striving for perfecting the manufacturing processes, innovative manufacturing ideas, its production and comprehensive economic indicators lies in the forefront of the same line, The products have been sold all over the country and exported to more than 30 countries and regions such as Indonesia, South Africa, Ukraine, Nepal, Indonesia, Kazakhstan, Iran, Korea, Vietnamese, Pakistan, Romania, Serbia and so on.

Refining Description

Degumming section: Degumming is the first and basic step in the crude oil refinery plant, degumming process aims to removing the gum impurities in the crude oil to make it suitable for further refinery process, hydration degumming and special acid degumming are the two main methods.

Deacidify system: The deacidify system uses versatile neutralization technology, which is developed to deal with oilseeds of different species and qualities in the oil refining plant, it can realize both degumming and neutralization processes by adding alkali, water and acid, then with FFA, crude phospholipids and moisture all removed, the oil and by products (soap foot, phospholipids) are separated.

Bleaching system: The oil bleaching is also named decolorization in oil refinery processes. This process’s main purpose is to remove the product of oxidation, pigments, phospholipids, soap materials from the oil. In the oil refinery plant, this process can improve the oil color as well as supplies high quality oil for the deodorization process.

Deodorization system: Deodorization section is very crucial in edible oil refinery plant in first grade oil production as it improves the flavor of the oil; the quality of deodorization equipment has great effect to the oil quality.

Products ShowPacking & DeliveryOur CertificationsOur Service

We have reliable after-sales

1. Pre-sale services:

1) Selecting equipment type;

2) Designing and fabricating the products in accordance with the special requirements of the clients;

3) Training technical personnel for our clients;

4) Providing construction and technology consultations or working out proper construction schemes for those new, special or difficult projects

2. Services provided during the sale:

Respect our clients; present the clients with ease, relaxation and a surprise; devote ourselves to improve the total value of our clients.

1) Checking products acceptance ahead of delivery;

2) Introducing the service system to our clients.

3. After-sale services:

Improve the added value of our products, and let the clients free from the using troubles:

1) Assisting the clients preparing for the first construction scheme;

2) Installing and testing the equipments;

3) Training the first-line operators on site.

Qie ExhibitionFAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: This depends on the machine size and production scale, we will complete the production as soon as possible and keep informing you the schedule.

Q: How long is the guarantee?

A: We promise one year guarantee for non-human damage factor.

Q: How to operate the machines?

Our engineers will train the worker how to operate it during installation and commissioning.

Technical parameters of 100Tpd Palm Kernel Oil Production Line Machine in Kenya

| Voltage | 240V or 380V or according to your request |

| Power(W) | KW |

| Dimension(L*W*H) | containers |

| Certification | ISO and CE certification |

| After-sales Service Provided | Engineers available to service Machine overseas |

| color | silver |

| type | palm oil refinery |

| Use | |

| description | semi-continuous or full continuous Palm oil refining equipments |

| steam consumption | 450kg/T oil |

| phosphoric acid | |

| electric consumption | 28kwh/T oil |

| Bleaching earth consumption | 5~50Kg/Toil |

| Waste bleaching earth oil content | <35% |

| Deodorization loss consumption | ≤0.5% |