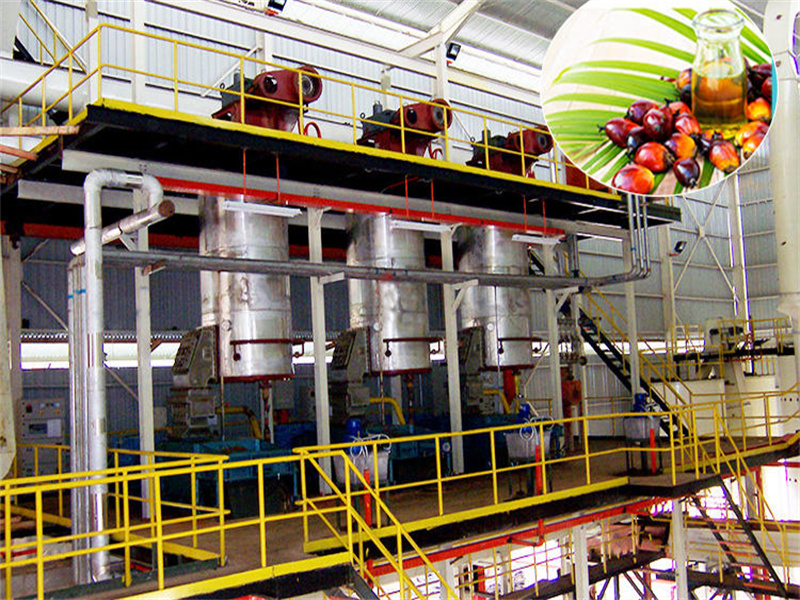

50Tph Palm Fruit Bunch Oil Maker Machine in Papua New Guinea

- Condition: New, New

- Usage: Palm Oil, Refine crude oil of Farm machienry

- Type: oil processing machine, Palm oil processing machine

- Automatic Grade: Automatic

- Production Capacity: 100%

50Tph Palm Fruit Bunch Oil Maker Machine in Papua New Guinea Description

20T/D palm kernel expeller processing machine

Palm kernel oil expeller processing flowchart:

Palm kernel—crusher—cooker—-pre-press—second press—-filter——cruder palm kernel oil—–enter into oil refining workshop

Palm kernel oil in one of high oil content oil material,so it passed twice press,and the residual oil is less than 8% at last.

Palm kernel cooker introduction:

You can see from above picture,there are 4 layers.It is one of main equipment in oil processing and used for cooking oil plants flakes.Namely,it processes raw flakes to ripe flakes by wetting,heating and cooking,which is good for oil making and improving oil quality.It may be aslo used for cooking other flakes in industries like food,pharmacy and chemical industry.

Palm kernel cooker introduction:

These pressers are big capacity,and they are made with cooker together as an integrate.And they were cotrolled by electrical control cabinet as flows:

Palm kerenel oil expeller machine auxiliary parts:

|

No |

Name |

Model |

Q.T.Y |

|

1 |

Motor |

90KW |

1 |

|

2 |

Motor belt pulley |

90KW |

1 |

|

3 |

Belt |

C5004 |

8 |

|

4 |

Belt cover |

1 |

|

|

5 |

Motor slide |

2 |

|

|

6 |

Adjusting bolt |

2 |

|

|

7 |

T model bolt |

4 |

|

|

8 |

Pressure gage |

1 |

|

|

13 |

Certification |

1 |

|

|

10 |

Feed shaft |

1 |

|

|

11 |

Auxiliary cooker |

1 |

|

|

12 |

Specification |

1 |

If small palm kernel processing capacity,you can adapt the flowing palm kernel oil expeller,and match a cooker before palm kernel pressing:

Palm kernel expeller machine pressing technology:

We supply different pretreatment methods for oil plants with different oil content. Generally, for high oil plants such as rapeseed, cottonseed and peanut, first prepress to the reasonable level and then extract. At present, screw oil press is used for prepressing, and it includes single screw and double screw oil press. Single screw oil press is of short stroke, high pressure, high-temperatured barrel and large capacity, while double screw oil press is of low-temperatured barrel because of double stoke. Single screw oil press is used when there is no specific requirements for temperature, and double screw oil press is used for required pressing under low temperature. When oil press operating, the prepared materials enter the pressing chamber from the hopper and then move forwards by the rotating of pressing screw and is pressed under the high-pressure condition in the chamber, friction between material and chamber will be created, which also created friction and relative movement among material particles, on the other hand, root diameter of the pressing screw carries larger from one end to the other. hence, when rotating, it not only pushed particles moving forwards but also turns them outwards as well, meanwhile, particles adjacent the screw will rotation along with screw’ rotating, causing every particle inside the chamber to possess different speed, therefore relative movement among particle creates heat which is necessary during manufacturing. because of helping protein change property, damage colloid, increase plasticity, decrease oil’s elasticity, resulting in high oil productivity.

Palm kernel oil processing machine Adapt to many oil materials:

Company Information

Our main business:

1. 10-500T/H oil material first cleaning,drying and storage section turn-key project.

2. 100-3000 T/D oil pretreatment, shelling and pre-press workshop turnkey project (soybean hot peeling, bean skin crushing; the soybean extrusion, high oil contained pre-press cake extrusion, and high oil contained embryos puffed; of direct puffed). Rice bran production line turn-key project.

3. Leaching workshop turnkey project (Towline extractor, Rotocel extractor, loop type extractor, DTDC separated machine, the full negative pressure evaporation, paraffin wax recovery, leaching workshop degum, phospholipid concentrate).

4. 30-1000T/D oil continuous grade two or one physical (chemical) refining production line.

5. 10-600T/D sunflower oil, rice bran oil, corn germ oil dewaxing turn-key project

6. 10-200T/D Fatty acid esterification production cooking oil production line.

Packaging & Shipping

Technical parameters of 50Tph Palm Fruit Bunch Oil Maker Machine in Papua New Guinea

| Model Number | 6YL |

| Voltage | 220V/380V/440V |

| Power(W) | 123kw |

| Dimension(L*W*H) | 18*10*16 meter |

| Weight | 1200kg |

| Certification | CE&ISO&BV |

| After-sales Service Provided | Engineers available to service Machine overseas |

| Origin | China |

| After-sale service | 1 year warranty |

| Processing material | Crude edible oil/palm oil/sunflower oil/corn oil/rice bran oil |

| Processing capacity | 1 Ton to 600 Ton per day |

| Final product | High quality edible cooking oil |

| Color | According to facility usage |

| Advantage | Energy Saving |