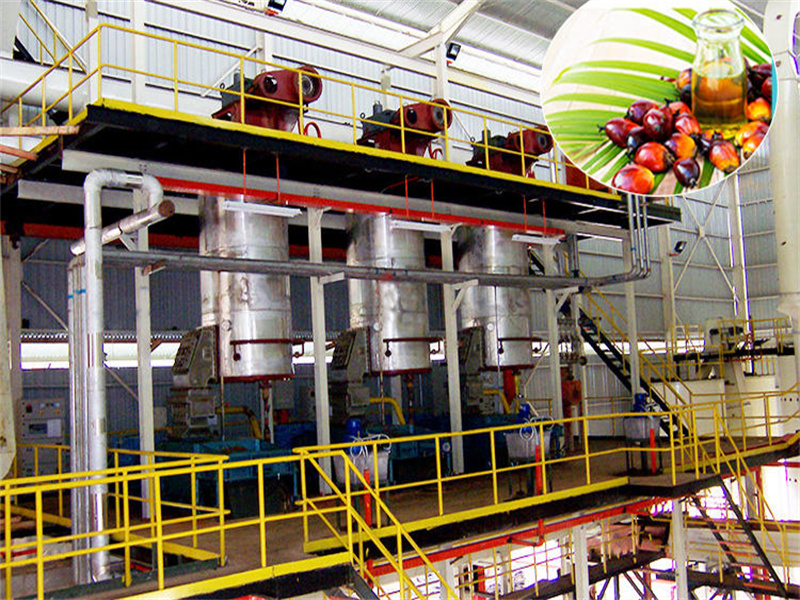

Palm Oil Factory For Sale in Malaysia

- Usage: edible oil, all kinds of vegetable seeds

- Type: palm oil refinery

- Automatic Grade: Automatic

- Production Capacity: palm oil refinery

- Model Number: palm oil refinery, palm oil refinery

Palm Oil Factory For Sale in Malaysia Description

High quality palm oil pressing machine/palm oil refining machine/palm oil extraction machine palm oil press flow chart

palm oil main process introduction

palm oil press machine:

Palm fruit reception:Transport FFB to reception station, flow to the scraper conveyer, conveyed to sterilizing station.

Sterilizaiton: FFB transported by scraper conveyer fall into sterilizing tank, make FFB soft,get more oil yield. sterilizing time 90~120mins, temperature 130~145°C

Threshing: After sterilizing, fruit bunch transported to thresh machine, separate palm fruit and empty fruit bunch.

Digesting: Before press palm fruit, should be crushed separated pulp and kernel.

Oil press:After crushing and digesting, the maxture of palm fruit and kernel fall into special palm oil presser.

Clarification:Filter the oil and use centrifuge to separate oil and impurities.

Kernel recovery:After press, the kernel and cake will be transported to kernel recovery station. Separating nut and shell, then go to kernel oil press.

Kernel pressing:We have developed cold and hot press,keep good quality palm kernel oil and high oil yield,meanwhile increase the press capacity,and reduce equipment investment.

palm oil refining machine:

Crude oil — degumming — deacidify — bleaching — deodorization

Degumming: Usded to neutrilizing ,and water washing,to rid off the acid .

deacidify :Acid stripping is removing hair oil contained in the free fatty acid process, acid stripping methods of alkali refining, steam distillation, solvent extraction, etc. Bleaching: Put activated clay(the weight of clay is 1%-3% of oil) in the oil to adsorb pigment and other impurities in oil ,achieving the purpose of purification .Temperature:80-110℃;Time:10-30min.

Deodorization: In order to remove bad smell,under vacuum and high temperature.

Our company

Our Company

XinxiangJinxin Chemical engineering equipment co,. Ltd is mainly focused on all kinds of pressure vessel and machine manufacturing .It is established in 1978 and has much rich experience in this field . .And our best seller is peanut oil Machine .We produce the complete oil production line ,and sell to all the world ,such America , Middle east ,Africa ,Europe etc.

FAQ

Q:Which kind of materials can be processed?

All kinds of oil seeds. For example, sunflower seeds, rice bran, corn germ, palm fruit, coconut,peanut, soybean, sesame, cottonseeds, rapeseed, etc.

Q: How long is the warranty?

The main parts of the machine come with one year warranty and after the expiration our engineer is available overseas to do the maintenance work.

Q: Can the machine be installed locally?

With our company’s turnkey project, our services range from installing the equipment locally to training staff.

Q: How to operate the machine?

Our engineers will be available to teach working staff how to run the machine.

If any questions, please feel free to contact me at anytime.

Technical parameters of Palm Oil Factory For Sale in Malaysia

| Voltage | depend on palm oil refinery, depend on the capacity |

| Power(W) | depend on palm oil refinery, depend on the capacity |

| Dimension(L*W*H) | depend on palm oil refinery, depend on the capacity |

| Weight | depend on palm oil refinery |

| Certification | ISO9001 |

| After-sales Service Provided | Engineers available to service Machine overseas, Engineers avto service Machine overseasailable |

| Steam consumption | based on palm oil refinery |

| Color | based on palm oil refinery |

| Residual oil in meal | Less than 1% |

| Crude oil moisture and volatile matter | Less than 0.30% |