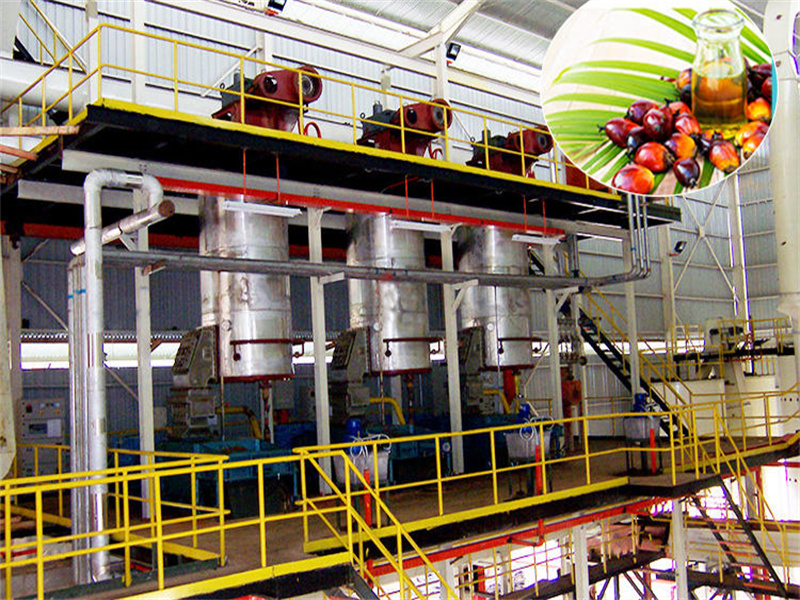

High Efficiency Palm Oil Processing Machine in Indonesia

- Usage: palm oil refining

- Type: Cold & Hot Pressing Machine, Continuous

- Automatic Grade: Automatic

- Production Capacity: 100-4000TPD

- Model Number: QIE-40

High Efficiency Palm Oil Processing Machine in Indonesia Description

DISCOUNT! high efficiency palm oil processing machine

Product description

?. 1.palm fruit/bunch → sterilization → threshing → digesting → clarification → purification →drying→ CPO

CPO → refining → bleaching → deodorizing →RBD palm oil → crystallization → fractionation → RBD olein & RBD stearin

1.1. Sterilizing function: easier to take off the fruit, removing bacteria and enzymes activity, to avoid the increase of free acid (FFA), improving the quality of oil.

1.2. Threshing function : remove empty string.

1.3. Digesting: Purpose is to destroy the fruit tissue heating medium oil and water emulsification state, which is formed by the lower the viscosity of the oil, and advantageous to the oil flow and precipitation.

1.4. Pressing function: Using special screw presser to press palm fruit for getting CPO.

1.5. Clarification: Clarifying: crude oil will be removed fiber by screen filter and goes into passivation tank, there is direct steam and indirect steam. Palm oil water mixture after purification by centrifugal pump into the high level oil tank, steady flow into clarification tank.

?.2.palm kernel →depericarper → crushing → pressing → CPKO → refining → RBDPK oil , RBDPK →olein & RBDPK stearin

?. 3. Crude palm oil standard

|

FFA |

<5 % |

|

Moisture |

<0.1 % |

|

Dirt |

<0.02 % |

Kernel Standard

|

Broken Kernel |

<15 % |

|

Moisture |

<7 % |

|

Dirt |

<6 % |

Company Information

Zhengzhou Qi’E Grain&Oil Machine Co.,Ltd has applied the automatic control system with advancedness, security, reliability into the pretreatment, extraction, refining and fractionation in large oil plants. For its application in automatic control system, it can control the production in the entire workshop and monitor the operational status of each device by controlling the computer terminals in the room. One person only can operate the entire workshop, with efficient production management. It has reduced the production cost greatly and improved the management efficiency.

Our Services

|

Pre-sale |

System evaluation: 1. Project basic situaction Solution: 1. The investment budget 2. Site measurement 3. Technical discussion Product selection: 1.Factory inspection 2. Site measurement 3. Technical discussion 4. Supply professional drawing and lists Win-win cooperation: 1. Sign the contract 2. Wstablish mutual benefit, strategic cooperative partnership. |

|

In-sale |

Design evaluation: 1. Detailed technical assessment, arrangement 2. Design of process and equipment layout Procurement: Strictly inspection, optimized selection. Installation: 1. Quality and quantity guaranteed 2. Completion of hand over Acceptance: 1. Acceptance test 2. Accepted deliverables Technical traning: 1.On-site installation and products training 2. Operation skills training 3.Maintenance training 4. Centralized technical training |

|

After-sale |

Technical service: Long time technical service Accessories supplying: Supplying spare parts with cost Complaint handling: 12-24 hours response mechanism Client Review: 1. Call-back 2. Regular return visit. |

Customer evaluation

1. The Zhengzhou Qi’e grain and oil Machine company’s experts guide installation and have good technology.

We make the cooperation with Qi’e group many times. Their experts guide installation on-site and after-sales team provides 24 hours of technical services.

I think they have done a well in this respect. Among the large number of grease equipment manufacturers, they are very good in China. Hope we can continue to cooperate in the future.

2. Zhengzhou Qi’e grain and oil Machine company’s equipment have good quality, and shipped on time.

We make the cooperation with Qi’e group for long time. Because they are manufacturer, their equipment have good quality assurance and reasonable price. They shipped on time after we finish contract.

Contact me

Technical parameters of High Efficiency Palm Oil Processing Machine in Indonesia

| Voltage | 220V / 380V / 440V |

| Power(W) | 30KW |

| Dimension(L*W*H) | 1200*2800*1200mm |

| Weight | 1200 Tons |

| Certification | CE/ ISO/ BV |

| After-sales Service Provided | Engineers available to service Machine overseas |

| solvent consumption | 1.5Kg/Ton materials |

| Oil Color | Yellow |

| Oil getting method | pressing/extraction |

| Heating way | steam |

| Advantage | save water resource |

| Bleaching earth consumption | 5~50Kg/T oil |

| Steam consumption | very low |

| decolor function | to get good color |

| deodor function | remove the bad smell |