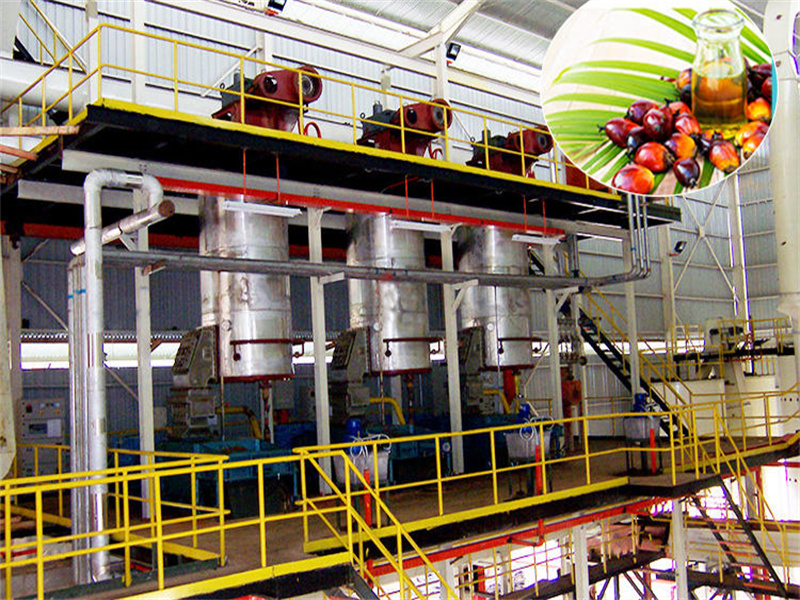

Crude Processing Palm Oil Processing Machine in Uganda

- Usage: Peanut Oil

- Type: Cold & Hot Pressing Machine

- Automatic Grade: Automatic

- Production Capacity: 5-100TPD

- Model Number: Qie

Crude Processing Palm Oil Processing Machine in Uganda Description

Introduction of palm oil expeller:

Automatic spiral oil press had meet in CE,ISO9001,BV. We had test for the following oil materials, Suitable type of Seed: Corn, Soybean,, Cashew, Camellia , Walnut ,Almonds, Sesame ,Peanut , Rapeseed and Pumpkin seeds and castor bean, olive seeds, palm seeds, coconuts, tea seeds, etc more than 30kinds had tested.

The machine including: pressing system, filtration system, storage tank 2 sets , heating system, power generator control panel.

Advantage of palm oil expeller:

1. Use high quality electroplate steel and stainless steel, durable, not easy to damage, Senior intelligent control, simple operation,Can trouble-free press seeds 150T yield.

2. Squeezing out of the filtered cooking oil, comply with the food safety standards and GMP standard.

3. Low temperature squeezing control technology,could start running on 30-50 degrees.

4. Economical, save electricity, just 15 square metre, 1 employees can production.

5. Cold and hot pressing technical, Our patent technology, gear shift speed technologies, truly realize cold pressing and hot squeeze.— get governments certification, advanced than international

6. A double helix oil press equals two oil press, can obtain double benefits.

7. Military industrial manufacturing, quality No.1 made in china.

8. Perfect after-sale service system, the 1 year warranty, free replacement parts,lifelong supply the parts in duty.

9. When buy machine, factory acquiesce in prepared full set of sparepart together with machines on shipment.

How to operate palm oil expeller:

1. Prepare the seeds;

2. Adjust the machine, such as electricity, heating (optional);

3. Start the machine, putting seeds into the feeder;

4. Seed into the screw bolt , begin to press;

5. The crude oil comes out of the squeezing bolt, then flow into the board;

6. Go into the vacuum filter, using it for filtration;

7. After filtration, the oil comes out from the bottom of pipe.

Detailed Images

Main spare parts of palm oil expeller:

Worm, squeezing head, worm shaft, cage bar, heater ring, cake outlet, vacuum filter.

Our CompanyQi’e since 1982

We have been engaged in oil press machines and oil refining equipment for 35 years. We have rich experience in this field and foreign trade field. We are capable of projects designing, installation and debugging and all round turn-key projects of pretreatment, prepressing, extraction, refining, fractionation and the deep processing of oilseeds. Including: process design, Machine design, electric power distribution, automatic control, civil engineering,etc.

CertificationsOur Service

Our company always put the interests of customers,product quality and service as

first ,and always adhere to the”no best, only better” as our purpose. We will be commitment to provide high quality products with perfect site services and after-sales service. Now the specific commitments are as follows:

1.Ensure provide complete sets of equipment and accessories timely.

2.Ensure that one-time installation debugging acceptance.

3.To provide high quality material with preferential price.

4.Priority to provide customer our new craftworks and products.

5.Free training technological operator to ensure the trained staff can operation independently.

6.In the installation process,we will appoint an installation supervision staff on the spot.

7.we will offer an experienced project manager, organize a good installation team for the work.

Contact us Packing & Delivery

Technical parameters of Crude Processing Palm Oil Processing Machine in Uganda

| Voltage | 230V-380V-430V |

| Power(W) | 40kw/h |

| Dimension(L*W*H) | 20m*16m*15m |

| Weight | 30tons |

| Certification | CE&ISO9001 |

| After-sales Service Provided | Overseas third-party support available |

| Machine type | Crude Palm Oil Processing Machine Refinery Equipment |

| Machine application | peanut oil |

| Operation time | 24hours |

| Electrical control | PLC control |

| Workers needed | 2-3persons |

| Machine material | carbon steel or stainless steel |

| Power consumption | 22KWH/T oil |

| Steam consumption | less than 300kg/t oil |

| Soft water consumption | about 160kg/h |

| Warranty period | 1year |