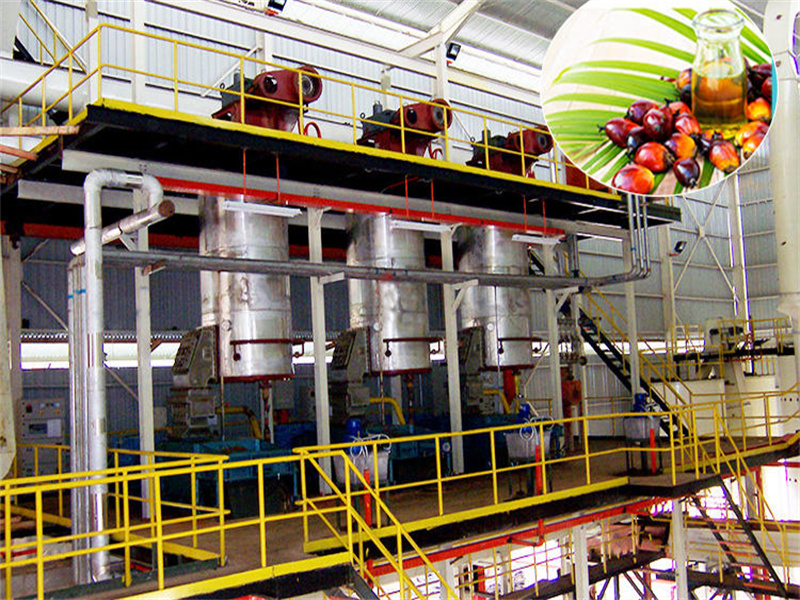

High Yield Rate Palm Kernel Oil Mill Machine in Colombia

- Condition: New, New

- Usage: Palm Oil, Refine crude oil of Farm machienry

- Type: oil processing machine, small crude palm oil refinery equipment

- Automatic Grade: Automatic

- Production Capacity: 100%

High Yield Rate Palm Kernel Oil Mill Machine in Colombia Description

Professional palm oil processing equipment manufacture,fresh plam fruit oil production

Safety:

1. we using auto welding machine to make the reactor,which can guarantee the quality of welding seam,avoid cracking and has a long life for about 8 years.

2. professional heating treatment and x-ray detection chamber for welding seam .

3. vacuum system to prevent oil gas be back to reactor causing accident.

4. with professional thermometer , profession pressure gauge and safety valve.

Environment friendly:

1.de–dusting system to prevent gas and dust from coal burning

2.the exhaust gas will be recycled for heating reactor ,no gas pollution

3.well sealing on every junction parts to prevent gas leak,no smelly

Longer life :

Using Q345R special steel plate ,welding seam with auto welding an will get heating treatment and x-ray detection to extend the life of reactor to the most extend, and the life will 8 years

Energy saving:

1. well sealing for heating system ,no gas leak and saving fuel.

2. the exhaust gas will be recycled for reactor heating.

1. Fruit peeling and pressing process

Reception station: A,The FFB bunches will be transported to factory by truck, after be weighted by weighting bridge, the FFB will be loaded down to FFB Loading Ramp.

A,The FFB bunches will be transported to factory by truck, after be weighted by weighting bridge, the FFB will be loaded down to FFB Loading Ramp.

B,The iron door of unloading ramp is controlled by hydraulic device, Get the power from Hydraulic pump station. Starting on the hydraulic device, iron door be lifted. FFB will fall down to the Palm Fruit screw conveyor, and transported to pre-treatment plant, to Sterilizers.

Sterilizing process:

A,By Scraper Conveyor, FFB be transported to the top of sterilizing tank. Falling into sterilizing tank from feed inlet.

B,Sterilizing tank: The inside diameter of sterilizing tank is φ2000mm, length 12500mm, welded up by Q235B material (Chemical composition:C0.12~0.2%,Si0.12~0.3%,Mm0.3~0.7%,P<0.045%,S<0.045%,Cr<0.3%,Ni<0.3%,Cu<0.3%).

C,After FFB be transported into sterilizing tank (202), close the door of sterilizing tank, and open the vent valve behind

the tank, then saturated steam, which pressure is 3bar and temperature is about 130°

D.After all the cooling air have been discharged out,close vent valve, proceed to sterilizing section. Sterilizing takes

55~60minutes. E,The time of sterilizing is also according the kind of FFB, if the pressure is too high or the time is too long , palm fruit will be rot, also Resulting in the loss of oil, high temperature can change palm color.

F, Finish sterilizing process, close the steam valve, open the valve lead to Blow-off/down Silencer, can’t open the sterilizing tank door until discharges out all steam and water.

G, Open the sterilizing tank door, sterilized FFB will fall on the FFB Scraper conveyor. Be transported to next station.

palm oil machine press:

A, The palm fruit is transported to Crush tank by fruit elevator.

B, The fruit in crush tank will be heated to 90~95°C, crush time is 10~20 minutes.

C, The pounded fruit flow into Palm fruit oil presser to press. Oil press cone can control cylinder, working pressure is 50~70bar, revolving speed of presser main shaft is 12.5 r/min. Meanwhile the mixture of crude palm oil and water Storage oil tank through crude oil groove. Then oil will be pumped to Screening filte by oil pump. After filtering take out the oil foam, deposit impurities. Palm oil flow into Passivating oil tank. The fiber cake and nucleus are exhausted from clearance of cone head drop on Breaking cake auger.

Weighting—Reception–Sterilizing threshing—–Digesting—– Mashing—- Pressing —- Depositing &Purification—-Filtering —-Palm crude oil

2. Palm kernel recycling and pressing process

Pressing cake —- Crushing—-Separating fiber&kernel —– Crusher —– Kernel&peel separator —-Kernel dryer—- Drying kernel —–Crushing —– Pressing

Packaging & ShippingCompany Information

1.Our company has been set up since 1982, It has been awarded the “The quality-star

enterprise of China” 2.Our factoru is also a group enterprise integrating scientific research, manufacturing,

sales as one.

3.We have cooperated with Research Institute of Machine Design Company and Henan,

Henan University of Technology (formerly the Zhengzhou Grain College) school-enterprise

cooperation in the oil equipment to carry out long term, protein extraction, phospholipid

extraction, etc. R & D and application of new technologies. 4.We have more than 200 employees ,among them ,there are 20 engineering technical personnel who hold intermediate and senior professional titles, and two highly reputed

professors. 5.We have exported our machines to Moscow, Romania, Pakistan, India, Bangladesh,

Thailand, Indonesia, Nigeria, Malaysia, Tunisia, and so on. Our new customers can visit

our demo machines in different countries.

Laboratory :

Customer visiting:

Certifications :

FAQ

1. Q: Which kind of materials can be processed?

A: All kinds of oil seeds. For example, rice bran, corn germ, cottonseeds, peanut, sunflower, soybean, rapeseed, etc.

2. Q: What’s the capacity?

A: 5-2000 tons per day.

3. Q: The materials of our machine?

A: The stainless steel and carbon steel.

4. Q: Can you install the machine in local place?

A: We will send our engineers to local place to help installing the machine.

5. Q: How to operate the machines?

A: Our engineers will train the worker how to operate it after running.

Technical parameters of High Yield Rate Palm Kernel Oil Mill Machine in Colombia

| Model Number | DY-small crude palm oil refinery equipment |

| Voltage | 220/380/400voltage |

| Power(W) | 123kw |

| Dimension(L*W*H) | 18*10*16 meter |

| Weight | 89600kg |

| Certification | CE&ISO&BV |

| After-sales Service Provided | Engineers available to service Machine overseas |

| Origin | China |

| After-sale service | 1 year warranty |

| Processing material | Crude edible oil/palm oil/sunflower oil/corn oil/rice bran oil |

| Processing capacity | 1 Ton to 600 Ton per day |

| Final product | High quality edible cooking oil |

| Certificate | CE&ISO&BV&TUV |

| Color | According to facility usage |