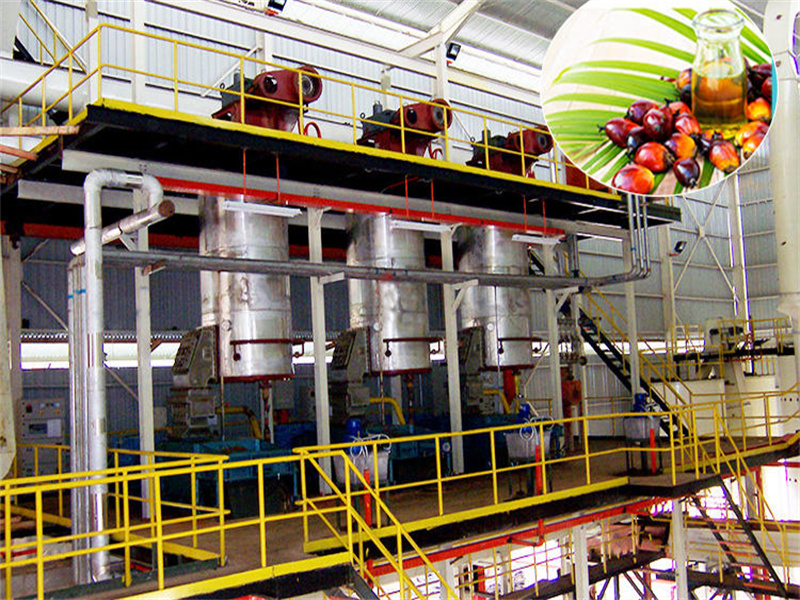

Palm Kernel Oil Production Line Machine/Palm Oil Processing Machine

- Usage: Palm Oil

- Type: palm oil refinery plant process

- Automatic Grade: Automatic

- Production Capacity: 98%

- Model Number: palm oil refinery plant

Palm Kernel Oil Production Line Machine/Palm Oil Processing Machine Description

Good quality palm kernel oil extraction machine in nigeria

Our Services

The whole palm kernel oil extraction machine contains three workshops: peanut pretreatment machine, peanut oil extraction machine and peanut refining machine. What kinds of oil seeds we can process?

palm kernel oil extraction machine

Product Description

1. Craft flow for palm kernel oil extraction machine.

palm kernel→Magnitic seperating( Metal impurities)→cleaning →husking→ flaking roll→Cooking →pressing-Workshop Main Equipments: 1. Palm kernel: It’s one of main oil seeds from human. It’s used to make peanut oil around the world. The oil content in peanut is about 35%.

2. Magnetic box: Clearing the iron impurity which might be in the peanut, The iron impurity will be harmful to the

following machines, so we need take the iron impurities out. 3.Cleaning: This parts have different size cleaning sieves to clean the different impurities.After going through this part,most of the impurities are moved from peanut.

4. Husking:this can help improve the oil yield from peanut,and reduce wear to the machine.

5. Flaking: It is the process of making use of the mechanical action to flake the peanut into flakiness. After flaking, the materials is becoming thiner thank before, it is good for absorb moisture and heat in cooking process , and it is much easier for getting peanut oil in the oil press process.

6. Cooker: This machine can adjust the water content of the peanut. It’s also good for the press and oil extraction section.

2.Craft flow for extraction of palm kernel oil extraction machine

A: Press: The press machine is used to take oil out of the peanut . After pressing,we can get crude peanut oil,and the oil residual in the cake is about 5-7%.

B. Solvent extraction machine: It is utilizing for extracting the maximum oil out from the peanut . The final oil residue is less than 1. It is usually suitable for processing large capacity oil seeds.

3. Craft flow for refinery of palm kernel oil extraction machine

Crude peanut oil → degumming and deacidification→ decolorization →deodorization → refined peanut oil.

Main Process: 1. Degumming and deacidification: The gumming is moved by phosphoric acid and hot water. There are two ways to move the acid in the peanut oil. One is chemical way, the other one is physical way. The chemical way is using NaOH to react with acid. This way issuitable for the capacity of 5-30T per day. The physical way is using steam and centrifugal to move the acid. This way is used for capacity from 30-2000T per day.

2. Decolorization: This step is used to adjust the color of the oil. You can control the color of the peanut oil according to the requirement of your market.

3. Deodorization: The function of this step is to move the special smell in the oil.This is an important standard for refined peanut oil. Certifications:

The specification of crude peanut oil

|

Item |

Standard |

|

Smell and taste |

The original smell and taste of soybean oil |

|

Moisture and volatile matter (%) ≤ |

0.20 |

|

Insoluble impurities (%) ≤ |

0.20 |

|

Acid value (mgKOH/g) ≤ |

4.0 |

|

Peroxide value (mmol/kg) ≤ |

7.5 |

The specification of refined peanut oil

|

Item |

Standard |

|

Color (Lovibond Cell 133.4mm) ≤ |

R2.0 Y20 |

|

Smell and taste ≤ |

No smell and good taste |

|

Transparence ≤ |

Clear and transparent |

|

Moisture and volatile matter (%) ≤ |

0.05 |

|

Insoluble impurities (%) ≤ |

0.05 |

|

Acid value (mgKOH/g) ≤ |

0.20 |

|

Peroxide value (mmol/kg) ≤ |

5.0 |

|

Smoke point (°C) ≥ |

215 |

Company Information

FAQ

1. What our other machines can do?

We have pressing machine, solvent extraction machine, and refinery machine, our press/expeller can get cold pressed oil or hot pressed oil from peanut, sunflower seeds, corn germ, cotton seeds, soy bean, rapeseeds and other oil crops; our solvent extraction line can extracte oil from various cakes by solvent(leaching),like soy cake, peanut cake, sunflower cake and others; Our refining machine can help you get refined oil(decoloring oil, degumming oil, deacid oil), 1st to 4th grade cooking oil as your requirements.

The biodiesel machine can produce International standard biodiesel, like EN14214 standard, ASTM 6751-03 standard, DIN V 51606 standard.

2. What’s your factory’s ability, which kind of machine do you manufacture?

We can produce all kinds of edible oil Machine, which includes palm oil production machine, peanut oil, soybean oil, cotton oil, sunflower oil, corn oil, rice bran oil and other kinds of edible oil.

The whole line includes oil press line, oil extraction (solvent) line, oil refinery line, palm oil fractionation line, sunflower oil dewaxing line, decoloring process, deodorization process and others.

We can produce biodiesel plant/Equipments also. On the other hand, our factory developed ourselves, import many advanced technology to strengthen ourselves and ensure our customer’s right.

3. Why always choose QIE?

A. More than 40 years’ manufacturing experience.

B.26 technical engineers research on new efficient processing craft and instruct manufacturing and installation work.

C.76 technicians in our professional installation team with rich and mature installation and training experience.

D. CE & ISO9001&BV&TUV certificate

If you are interested in peanut groundnut oil processing machine , please feel free to contact me.

Technical parameters of Palm Kernel Oil Production Line Machine/Palm Oil Processing Machine

| Voltage | 380V/440V |

| Power(W) | Depend on the palm oil refinery plant capacity |

| Dimension(L*W*H) | Depend on the palm oil refinery plant capacity |

| Weight | Depend on the palm oil refinery plant capacity |

| Certification | ISO9001 |

| After-sales Service Provided | Engineers available to service Machine overseas |

| product name | 300TPD palm oil refinery plant/palm oil refining process |

| Key word | palm oil refinery plant |

| Color | As your requirement |

| Materials of the equipment | stainless steel and carbon steel |

| Distillation range | 68-75℃ |

| Solvent residual after desolventizer | <300ppm |

| Deodorization loss consumption | ≤0.5% |

| Refining method | phisical or chemical as your requirement |

| Warrenty | 12months |