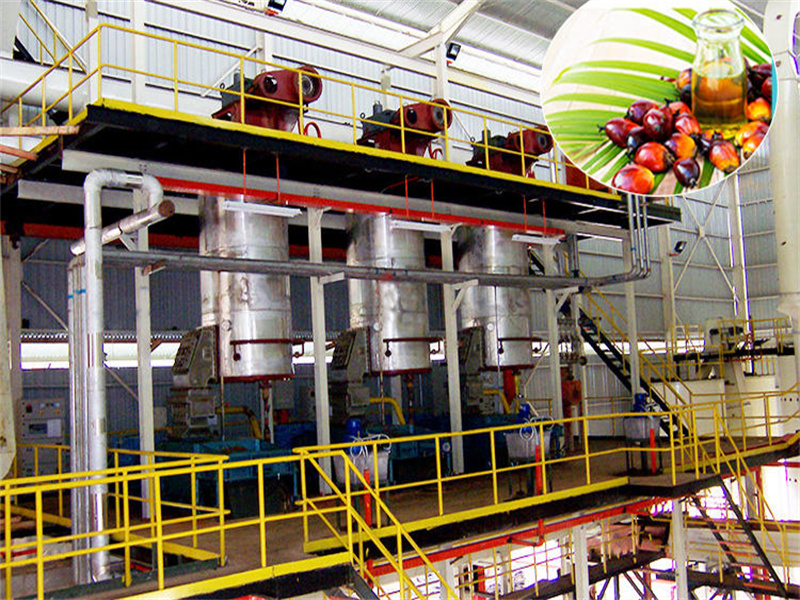

From 2Ton Per Hour To 80Tons Per Hour Palm Oil Production Process

- Usage: Palm Oil, Making palm oil

- Type: Cold & Hot Pressing Machine

- Automatic Grade: Automatic

- Production Capacity: 98%

- Model Number: According to specific model

From 2Ton Per Hour To 80Tons Per Hour Palm Oil Production Process Description

Palm oil leaching equipment virgin coconut oil extracting machine

Main Economic and Technical Parameters of Rotocel Extractor (take 300T soybean extraction as an example)

|

Capacity |

300T/D |

|

Residual oil in meal |

≤ 1% (soybean) |

|

Solvent consumption |

≤ 2Kg/T (No.6 solvent oil) |

|

Crude oil moisture and volatile matter |

≤ 0.30% |

|

Power consumption |

≤ 15KWh/T |

|

Steam consumption |

≤ 280KG/T (0.8MPa) |

|

Finished meal moisture |

≤ 13% (adjustable) |

|

Residual solvent in finished meal |

≤300PPM (qualified detonated experiment |

Raw material for leaching equipment Sesame ,peanut ,rapeseed ,cottonseed ,palm kernel ,corn ,olive ,cocunt ,rice bran ,

etc .

Principle of leaching make use of Dissolve grease solvent ,which make oil and fat extracted from oil flakes ,by wetting and penetration, Molecular diffusion and Convection-diffusion .

Process of leaching oil

Pretreatment – oil leaching – wet meal desolventizing – mixed oil evaporation and steam stripping -solvent recycle .

Methods of leaching oil

immersion extracion ,spray-type, mixing type Reques of wet meal desolventizing

moisture less than 8.0 to 0.9% residual solvent less than 0.07% meal termperature obove 105 degree or below 70 to 80 degree Process of oil extraction

The prepared material enters the solvent extractor through the rotary air seal. The solvent extractor consists mainly of a very slow moving articulated band conveyor inside a totally enclosed chamber. The band is lined with perforated sheets and porous stainless steel cloth. The mass of the material moving on this band forms a slow moving bed. During the movement of the bed through solvent extractor it is washed continuously at various points with miscella of decreasing concentrations and finally with a fresh solvent in a counter current manner by means of sprayers kept in a line over the meal bed. The miscella percolates through the perforated bottom and collects in various hoppers kept below the bed. The miscella from the last hopper, which is concentrated, is taken off for distillation.

Picturer of products

company image

contact me

welcome to order from us

Technical parameters of From 2Ton Per Hour To 80Tons Per Hour Palm Oil Production Process

| Voltage | 380V |

| Power(W) | According to specific model |

| Dimension(L*W*H) | According to specific model |

| Weight | According to model |

| Certification | ISO CE, CE /ISO |

| After-sales Service Provided | Engineers available to service Machine overseas |

| Name | New technology palm oil machine |

| Material | Carbon Stee l Stainless Steel |

| Application | Producing palm oil |

| Advantage | new technology |

| Warranty | 12 Months |

| Application range | palm oil |

| Feature | no waste water,air,pollution |

| Product name | new technology palm oil making machine |