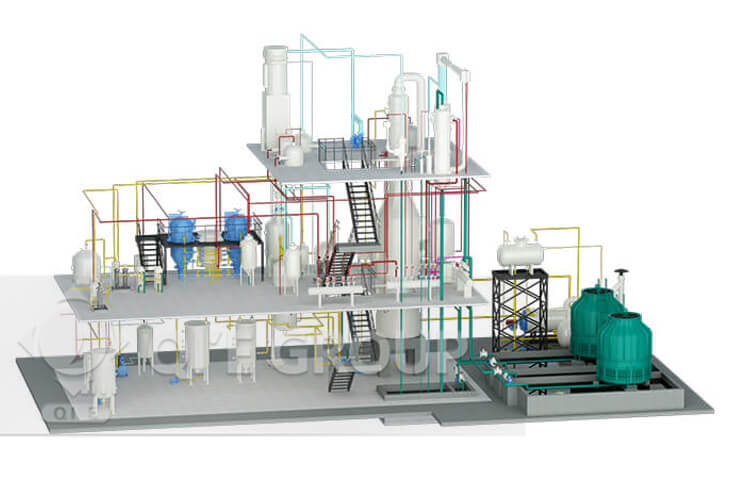

Palm Oil Fractionation Plant

- Production Capacity: 10-1000TPD

- Type: Oil Fractionation

- Application: large, medium and small palm oil production line

- Advantage: Low Residual, Long Service Life, Easy Operation

- Machine Material: stainless steel or carbon steel

- Specification: International standard

Palm Oil Fractionation Plant Description

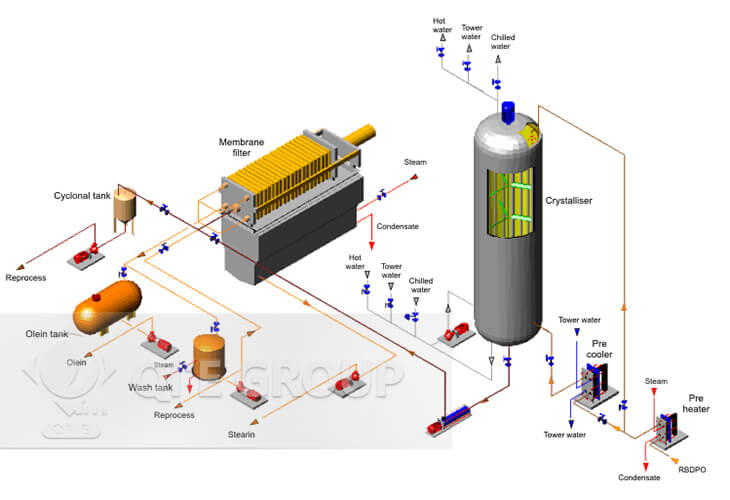

Palm Oil Fractionation Process Chart:

Dry palm oil fractionation includes three steps below:

1)Heat treatment

2)Form crystal nuclei and allow crystal growth and maturity by cooling method.

3)Filtration separates soft fat from solid.

One time fractionation is enough, but twice palm oil fractionation is in need for some relatively high demand industry of stearin, such as confectionery industry.

Major equipment: Crystal jar, Water-cooled screw chillers, Membrane filter press

Application: New type oil Fractionation technology applicable for palm oil, Cottonseed oil, ect.

Technical parameters of Palm Oil Fractionation Plant

| One heating tank, two cooling crystallization tanks | There is a thermal oil heating coil in the heating tank, and a cooling water coil in the cooling crystallization tank. The cooling crystallization tank is equipped with a stirrer to ensure that the cooling crystallization process is carried out evenly. |

| Plate filter | Plate filter is used to separate palm soft butter from hard fat. What comes out of the strainer is palm soft fat, which can be poured directly into the soft fat jar. The palm stearin taken from the middle of the filter plate is melted in the lower stearin tank and poured into the stearin tank. |

| air compressor | air cooling system is used to make cooling water for cooling crystallization tanks |