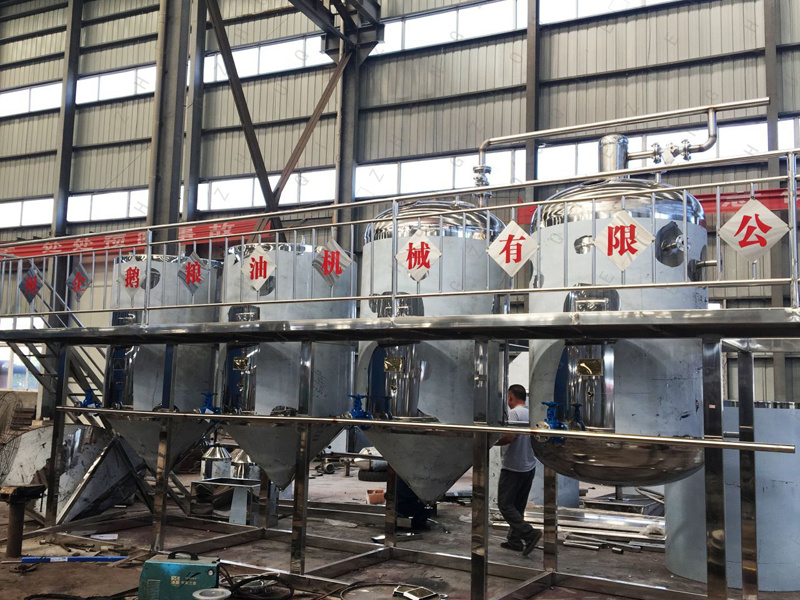

China Hot Sale Mini Crude Palm Oil Refining Mill in Nigeria

- Usage: palm oil equipment manufacturer

- Type: palm oil equipment manufacturer

- Automatic Grade: Automatic

- Production Capacity: 20TPH-80TPH

- Model Number: QIE133

China Hot Sale Mini Crude Palm Oil Refining Mill in Nigeria Description

Supplier for palm oil processing machine in nigeria

WHAT ARE THE RAW MATERIALS LIKE?

Reception station:

A. The FFB bunch be transported to plant by truck, after be weighted by weighting bridge, the FFB will be loaded down to FFB Loading Ramp.

B. The iron door of unloading ramp is controlled by hydraulic device, Get the power from Hydraulic pump station. Start on the hydraulic device, iron door be lifted. FFB will fall down to the Palm Fruit screw conveyor, be transported to pre-treatment plant, to Vertical sterilizer.

Sterilizing process:

A. By Scraper Conveyor, FFB be transported to the top of sterilizing tank. Falling into sterilizing tank from feed inlet.

B. Sterilizing tank: The inside diameter of sterilizing tank is φ2000mm, length 12500mm, welded

up by Q235B material (Chemical composition: C0.12~0.2%,Si0.12~0.3%,Mm0.3~0.7%,P<0.045%,S<0.045%,Cr<0.3%,Ni<0.3%,Cu<0.3%).

C. After FFB be transported into sterilizing tank (202), close the door of sterilizing tank, and open the vent valve behind the tank, then saturated steam, which pressure is 3bar and temperature is about 130°C. After all the cooling air have been discharged out,close vent valve, proceed to sterilizing section. Sterilizing time is 55~60minutes. D. The time of sterilizing is also according the kind of FFB, if the pressure is too high or the time is too long , palm fruit will be rot, also Resulting in the loss of oil, high temperature can change palm color.

E. Finish sterilizing process, close the steam valve, open the valve lead to Blow-off/down Silencer, can’t open the sterilizing tank door until discharges out all steam and water.

F. Open the sterilizing tank door, sterilized FFB will fall on the FFB Scraper conveyor. Be transported to next station.

Threshing station:

A. The sterilized FFB will be transport to thresher platform by scraper conveyor.

B. We adopt advanced Drum type thresher, insider diameter is φ1800mm, length is 5000mm.

The material of main shaft is #45 steel (main chemical composition is C0.42~0.50%, Si0.17~0.37%, Mm0.50~0.30%, P≤0.035%, S≤0.035%, Cr≤0.25%, Ni≤0.25%, Cu≤0.025%).

C. Sterilized FFB be twisted and knocked in thresher. Palm fruit will be separated from empty bunch totally, fall on Fruit Scraper conveyor though fence, the empty bunch will be transported to Bunch Temporary tank by Bunch Scraper conveyor.

Palm oil machine press:

A. The palm fruit is transported to Crush tank (401) by fruit elevator.

B. The fruit in crush tank will be heated to 90~95°C, crush time is 10~20 minutes.

C. The pounded fruit flow into Palm fruit oil presser(402) to press. Oil press cone can control cylinder, working pressure is 50~70bar, revolving speed of presser main shaft is 12.5 r/min. Meanwhile the mixture of crude palm oil and water outflow from barrel holes. Crude oil will be flow in Temporary Storage oil tank(T06) through crude oil groove. Then oil will be pumped to Screening filter(601) by oil pump. After filtering take out the oil foam, deposit impurities. Palm oil flow into Passivating oil tank(602). The fiber cake and nucleus are exhausted from clearance of cone head drop on Breaking cake auger (501).

D. Palm fruit oil presser (402), the material of main shaft is 40Cr steel, (Chemical component: C0.37~0.44%, Si0.17~0.37%, Mn0.50~0.80%, Cr0.80~1.10%) have been thermal refining, the material of worm and cone head is 45# Cast-teel, and the surface have quenching treatment.

Still have questions?

What should you do??

Do not worry!

SAM is always here!!

Just Contact SAM!!!

Technical parameters of China Hot Sale Mini Crude Palm Oil Refining Mill in Nigeria

| Voltage | 220V/380V |

| Power(W) | According to your Capacity |

| Dimension(L*W*H) | depend on the mode |

| Weight | depend on the mode |

| Certification | ISO9001 |

| After-sales Service Provided | Engineers available to service Machine overseas |

| Item | palm oil equipment manufacturer |

| After sale service | Yes |

| Oil extract rate | 21-23% |

| Oil content in press cake | 6 % |

| Oil content in final effluent | 0.6% |

| Kernel content in cyclone fiber | 0.15% |

| Kernel content in dry shell | 2% |

| Origin | China |

| Market | Asia, Africa, Southeast Asia |

| Brand | Qi'e |