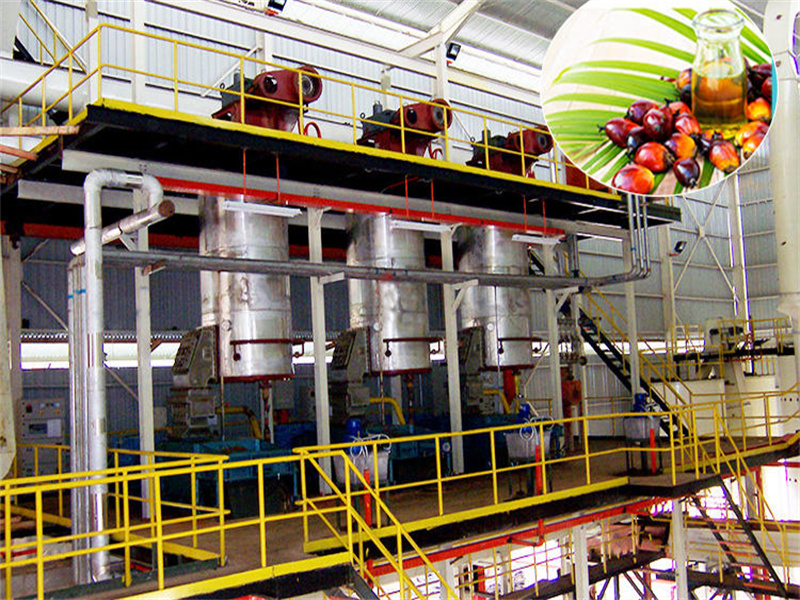

Complete in Specifications Of Edible Palm Oil Expeller Facility

- Usage: Sunflower Oil

- Type: Oil Refining Machine

- Automatic Grade: Automatic

- Production Capacity: 200TPD

- Model Number: Full-continuous

Complete in Specifications Of Edible Palm Oil Expeller Facility Description

palm oil production machine/ palm oil processing equipment

palm oil production machine

palm oil processing equipment

1.Introduction palm oil production machine/ palm oil processing equipment

Equipments which directly related to the palm fruit oil process (from fresh fruit to final products) are divided into six systems as follows:

1.Fruit reception system of palm oil production machine

1.1 Use truck to transport the ripe and fresh palm fruits from fruit ranch, weigh up them by platform scale and record, and then pour them into the discharging table.

1.2 Start control valve to open the discharging table , then fruit drop in the fruit basket car freely.

1.3 Drag the fruit basket car which loaded with fresh palm fruits to the downward of the bridge crane by power cable tray and cable tray, then use bridge crane to sling the fruit basket car to the track lead to sterilizer sterilizing tank. 2. Sterilizer system of palm oil production machine

2.1 After drag the fruit basket car into the sterilizer sterilizing tank, close the sterilizer sterilizing tank and open the vent valve below it. Then inlet saturated vapor, close the vent valve after the cold air in the tank was excluded generally, and enter into the period of steaming and sterilizing

2.2 Close the inlet valve after the sterilizing process. Drain out the water and vapor in tank, then you can open the door of the sterilizer sterilizing tank.

2.3 Drag the cooked fruit basket car to the downward of the beige crane

3.Threshing system of palm oil production machine

3.1 Pour the sterilized fruit in the fruit basket car into the unloading equipment.

3.2 Feed the fruit regularly into the fruit-separating machine to separate.

3.3 After twisting and beating in the fruit-separating machine, the fruits will fall off entirely.

4. Pressing system of palm oil production machine

4.1 Palm fruit was transported to crasher by elevator.

4.2 Fruit was heated in crasher.

4.3 After sterilizing, the broken palm fruit flow into the palm oil press machine to pressing. Oil and water mixture outflow from pressing chamber shell hole, in the same time, the fiber cake and core was discharged from bonehead clearance and then drop in the packing anger of broken cake.

5. Fiber, cake, shell and kernel separation system of palm oil production machine

5.1 Fiber cake was dropped into packing auger, use interrupted blade to break up the palm cake, evaporate the palm cake constantly during the transportation, and the enter into the fiber and core separation machine. Use induced draft system which compose of draught fan and wind net to transport fiber to boiler room to burn. Palm core of large proportion drops into the bucket elevator from the other side of the fiber and core separating machine and then to transport to the core charging bucket to dry.

5.2 Open the discharging hole which is at the bottom of the core chafing bucket, then palm core drop into husking machine to husk.

5.3 Use shell kernel separator to separate the shell and kernel mixture after husking.

5.4 Kernel are charged into kernel-holding tank and shell are transported to boiler room to burn.

6. palm oil refining and fractionation system

(1)Pump crude oil into refining tank and heat with conduction oil, and the temperature will reach about 70°C-80°C after one hour. Add acid or alkali to separate according to the acid value. After one hour’s processing and 4-6 hours deposit, then convey soap stock to storage tank.

(2)Pump refined oil into decoloring tank. When it is up to 90-110°c after one hour’s heating,add clay into tank for 20min’s processing. Then separate clay and oil with filter.

(3)Put discolored oil into deodorization tank with vacuum pump. Heat and process with steam for odor removal.After filtering, you will get final oil product.

palm oil production machine/ palm oil processing equipment advantage:

1.Our products have the high quality and high performance.we use the stainless steel instead

of the carbon steel.

2. We buy directly from the manufacturer for guaranteeing the quality.

3.Our welding worker should get the certificates.

4.Our electric machines all imported from Germany, like Simens motors.

palm oil production machine/ palm oil processing equipment consumption in operation:

|

Residual oil in cake |

≤5% (palm) |

|

Residual oil in fiber |

≤2% |

|

Crude oil moisture and volatile matter |

≤ 0.30% |

|

Power consumption |

≤ 15KWh/T |

|

Steam consumption |

≤280Kg/T (0.8MPa) |

|

Finished meal moisture |

≤ 10-13% (adjustable) |

2.Technical parameters of palm oil production machine/ palm oil processing equipment

Packaging & Shipping

Company Information

1.Our company has been set up since 1982, It has been awarded the “The quality-star

enterprise of China”

2.Our factoru is also a group enterprise integrating scientific research, manufacturing,

sales as one.

3.We have cooperated with Research Institute of Machine Design Company and Henan,

Henan University of Technology (formerly the Zhengzhou Grain College) school-enterprise

cooperation in the oil equipment to carry out long term, protein extraction, phospholipid

extraction, etc. R & D and application of new technologies.

4.We have more than 200 employees ,among them ,there are 20 engineering technical

personnel who hold intermediate and senior professional titles, and two highly reputed

professors.

5.We have exported our machines to Moscow, Romania, Pakistan, India, Bangladesh,

Thailand, Indonesia, Nigeria, Malaysia, Tunisia, and so on. Our new customers can visit

our demo machines in different countries.

Laboratory :

Customer visiting:

Certifications :

FAQ

1. Q: Which kind of materials can be processed?

A: All kinds of oil seeds. For example, rice bran, corn germ, cottonseeds, peanut, sunflower, soybean, rapeseed, etc.

2. Q: What’s the capacity?

A: 5-2000 tons per day.

3. Q: The materials of our machine?

A: The stainless steel and carbon steel.

4. Q: Can you install the machine in local place?

A: We will send our engineers to local place to help installing the machine.

5. Q: How to operate the machines?

A: Our engineers will train the worker how to operate it after running.

Technical parameters of Complete in Specifications Of Edible Palm Oil Expeller Facility

| Voltage | 220V/380V |

| Dimension(L*W*H) | According to capacity |

| Weight | According to capacity |

| Certification | ISO, CE, BV |

| After-sales Service Provided | Engineers available to service Machine overseas |

| Heating syetem | Heat-conducting oil |

| Soap tank | Soap pump |

| Steam consumption | 450kg/T oil |

| Phosphoric acid | 2~3kg/T oil |

| Electric consumption | 28kwh/T oil |

| Deodorization loss consumption | ≤0.5% |

| Circulating water cooling water yield | 150m³/H |

| Bleaching earth consumption | 5~50Kg/Toil |

| Waste bleaching earth oil content | <35% |

| Technology guide | With guidance personnel |