Crude Palm Oil Refining Equipment Agricultural Manchinery

- Usage: palm oil refinery plant

- Type: palm oil refinery plant

- Automatic Grade: Automatic

- Production Capacity: 1-1000TPD

- Model Number: palm oil refinery plant

Crude Palm Oil Refining Equipment Agricultural Manchinery Description

The main Parts of Hot sell of palm kernel oil refining machine:

Crude oil→ degumming → deacidify → bleaching → deodorization → Heat-transfer oil stove→ Steam generator→ Vacuum pump → Press filter→ Air compressor

1. Crude oil: crude palm kernel oil is commonly used for processing into edible oil .For example: palm oil,Sunflower oil,sesame oil,cotton seed oil,peanut oil,rice bran oil,palm oil,coconut oil,soybean oil,apeseed oil,mustard seed oil, palm kernel oil etc. 2. Degumming :Usded to neutrilizing ,and water washing,to rid off the acid .

3. deacidify : Acid stripping is removing hair oil contained in the free fatty acid process, acid stripping methods of alkali refining, steam distillation, solvent extraction, etc. 4. bleaching :Used to rid off the color of the oil

5. Deodorization:Used to rid off the fetid smell/odour of oil by steam understand of high temperature.

6. Heat-transfer oil stove: supply each device production needing heat energy, temperature reach above 280°C. 7. Steam generator: produce the needing steam for de-odoring and distillation.

8. Vacuum pump: supply needing vacuum for dehydrate, de-color, de-odor. Vacuum degree can reach above 755mm Hg.

9. Press filter: filter clay, filter out clear oil.

10. Air compressor: blow dry bleached clay, blow empty the leftover oil in the press filter.

The main process of Hot sell of palm kernel oil refining machine:

(1)Pump palm kernel crude oil into refining tank and heat with conduction oil, and the temperature will reach about 70°C-80°C after one hour.Add acid or alkali to separate according to the acid value. After one hour’s processing and 4-6hours deposit, then convey soap stock to storage tank.

(2)Pump refined palm kernel oil into decoloring tank. When it is up to 90-110°C after one hour’s heating, add clay into tank for 20min’s processing. Then separate clay and oil with filter.

(3)Put decolorizing palm kernel oil into deodorization tank with vacuum pump. Heat and process with steam for odor removal.After filtering, you will get final oil product.

The parameters of Hot sell of palm kernel oil refining machine:

|

Steam consumption |

450KG/T oil |

|

Electric consumption |

28Kwh/T oil |

|

Phosphoric acid |

2~3 kg/T oil |

|

Circulating water cooling water yield |

150m3/H

|

|

Bleaching earth consumption |

5~50Kg/T oil |

|

Waste bleaching earth oil content |

<35% |

|

Deodorization loss consumption |

≤0.5% |

Let me introduce our some main products about Hot sell of palm kernel oil refining machine:

This is degumming design drawing

Next is degumming equipment

This is bleaching design drawing

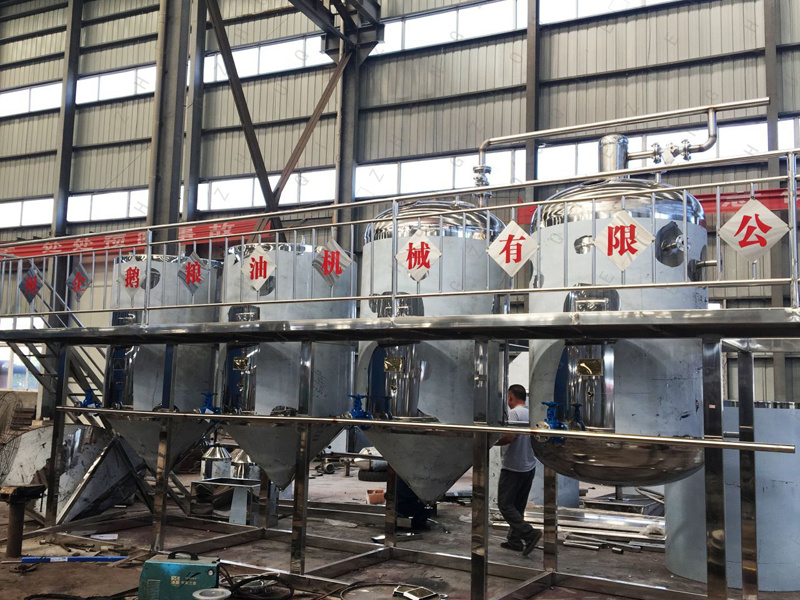

Next is bleaching equipment

This is Deodorization tower

Now look at our factory:

Our honor should be more convincing:

Welcome to contact me:

We factory is specialize in the production of grain oil Machine and equipment. We can provide high-quality equipments and the best service for you.Thanks.

Technical parameters of Crude Palm Oil Refining Equipment Agricultural Manchinery

| Voltage | 380V 410V |

| Power(W) | crude oil refinery machine |

| Dimension(L*W*H) | crude oil refinery machine |

| Weight | crude oil refinery machine |

| Certification | CE and ISO |

| After-sales Service Provided | Engineers available to service Machine overseas |

| Function | palm oil refinery plant |

| Warranty | 12 months |

| Raw material | crude mustard oil |

| final product | refined mustard oil |

| texture | stainless steel or carbon steel |

| coclor | according to customer |

| capcity | 1-4000TPD |

| service after sale | workshop design/installation |

| service life | 60 years |

| others | according to customer |