Good Sales Palm Oil Price in Indonesia in Kenya

- Usage: Palm Oil

- Type: Cold & Hot Pressing Machine

- Automatic Grade: Semi-Automatic

- Production Capacity: 100TPD

- Model Number: QIE-p034

Good Sales Palm Oil Price in Indonesia in Kenya Description

Specifications

Palm oil cake solvent:

1.Complete production line

2.Mature technology

3.Reasonable price

4.Professional

Super quality and competitive price automatic palm oil cake solvent hot sale in America and Europe

Palm oil is a common cooking ingredient in the tropical belt of Africa, Southeast Asia and parts of Brazil. Its use in the commercial food industry in other parts of the world is buoyed by its lower cost and by the high oxidative stability (saturation) of the refined product when used for frying.A recent rise in the use of palm oil in the food industry has come from changed labelling requirements that have caused a switch away from using trans fats.Palm oil has been found to be a reasonable replacement for trans fats, however a small study conducted in 2009 found that palm oil may not be a good substitute for trans fats for individuals with already elevated LDL levels. Method of germ extraction mainly half wet, wet and dry. Process Features:

1. Adopt stainless steel fixed grid plate and increase the horizontal grid plates, which can prevent the strong miscella from flowing back to the blanking case, so as to ensure good extraction effect;

2. The rotocel extractor is driven by rack, with unique rotor of balanced design, low rotating speed, low power, smooth operation, no noise and quite low maintenance cost;

3. The feeding system can adjust the rotating speed of airlock and main engine according to the feeding quantity and maintain a certain material level, which is beneficial to the micro negative pressure inside the extractor and reduce the solvent leakage.

4. The advanced miscella circulation process is designed to reduce the fresh solvent inputs, reduce the residual oil in meal, improve the miscella concentration and save energy by reducing the evaporation capacity.

5. The high material layer of the extractor helps to form immersion extraction, reduce the meal quality in miscella, improve the quality of crude oil and reduce the evaporation system scaling.

6. Specially suitable for the extraction of various pre-pressed meals.

Main Economic and Technical Parameters of Rotocel Extractor (take 500T corn extraction as an example)

|

Capacity |

500T/D |

|

Residual oil in meal |

≤ 1% (corn) |

|

Solvent consumption |

≤ 2Kg/T (No.6 solvent oil) |

|

Crude oil moisture and volatile matter |

≤ 0.30% |

|

Power consumption |

≤ 15KWh/T |

|

Steam consumption |

≤ 280KG/T (0.8MPa) |

|

Finished meal moisture |

≤ 13% (adjustable) |

|

Residual solvent in finished meal |

≤300PPM (qualified detonated experiment) |

Towline Extractor Process Features

1) The material is divided into several independent units on the material bed, which can effectively prevent miscella at all levels from fleeing hither and thither on the material layer and ensure the concentration gradient between several sprays.

2) Immersion area appears in each lattice, which can help achieve better immersion effect.

3) The chain box is supported by track and can prolong the service life of screen deck by not touching it. 4) The towline extractor is driven by world leading double-shaft hydraulic motor, with balance force, reliable operation and less maintenance cost.

5) Specialty suitable for the extraction of high oil and high power materials, and better immersion effect can be expected for ordinary oil plants. Main Economic and Technical Parameters of Towline Extractor (take 500T/D corn as an example)

| Steam consumption | ≤ 280kg/t (soybean) |

| Power consumption | installed capacity 320KW |

| Solvent consumption | ≤ 4kg/t (No.6 solvent) |

| Residual oil in meal | ≤ 1.0% |

| Moisture in meal | 12~13% (adjustable) |

| Solvent in meal | ≤ 500ppm |

| Urase activity | 0.05-0.25 (corn cake) |

| Total volatile matter | ≤ 0.3% |

| Residual solvent | ≤ 300ppm |

| Mechanical impurities | ≤ 0.2% |

Coconut oil extract machine refining machine:

1.Deacidification

Sodium hydroxide antagonize free fatty acids,and subside phospholipids,to remove the insoluble impurities,then after the separation of soapstock, neutral oil was washed in soft water,last drying in vacuum.

2.Decoloration

Corn oil pigments in two categories: one is the natural pigment, such as the carotenoids lutein materials such as chlorophyll, these are easy to bleach,and the other type of the products of organic matter, these pigments are not easy to be bleached.

3.Dewaxing

Dewaxing can ensure the colour of corn oil to be clear bright at room temperature and frozen temperature. to reduce the oil in the wax content to 10 parts per million to get crystal clear oil.

4.Deodorization

Using high temperature and high vacuum steam stripping method deodorization temperature commonly 180, vacuum degree 9.3 104 Pa can achieve ideal results

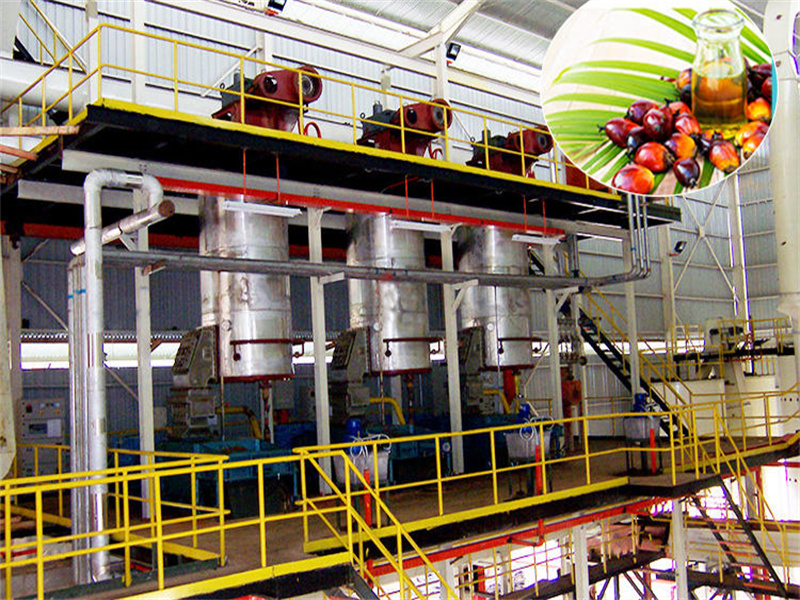

our workshop

Technical parameters of Good Sales Palm Oil Price in Indonesia in Kenya

| Voltage | 220V/380V |

| Power(W) | 18.5KW |

| Dimension(L*W*H) | 1200*2800*1200mm |

| Weight | 30tons |

| Certification | CE/ ISO/ BV |

| After-sales Service Provided | Engineers available to service Machine overseas |

| Product name | edible palm oil fractionation plant construction |

| Machine Material | Stainless Steel Oil Press |

| Warranty | One Year |

| Work principle | mechanical extruding |

| Export markets | Europe, Southeast Asia, Africa, etc |

| Raw material | Palm Fruit |

| Feature | High Output |

| Application | Palm oil |

| Character | Oil Processing Line |

| Function | Oil Production |