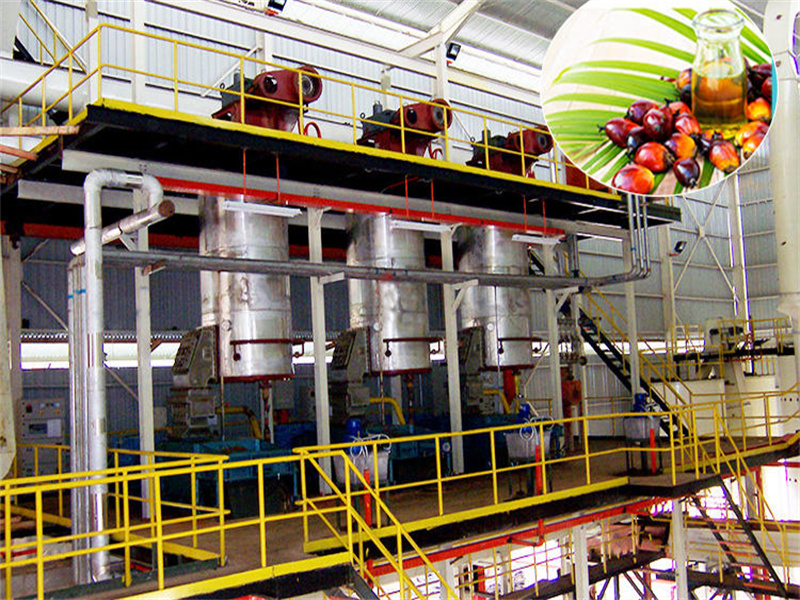

High Yield Rate Palm Oil Making Machine in Indonesia

- Usage: palm kernel

- Type: Cold & Hot Pressing Machine

- Automatic Grade: Automatic

- Production Capacity: 50-3000TPD

- Model Number: Depend on plam kernel oil output

High Yield Rate Palm Oil Making Machine in Indonesia Description

palm oil refinery process machine:

Refinery workshop details:It includes degumming section ,deacidification

It adopts advanced plane turning screen and stone separator to clean oil plant,and then crash,flake,cook,mill and filter them. It has advanced techniques and high automatization level

Main economic technical parameters:

|

Steam consumption |

450KG/T oil |

|

Electric consumption |

28Kwh/T oil |

|

Phosphoric acid |

2~3 kg/T oil |

|

Circulating water cooling water yield |

150m3/H |

|

Bleaching earth consumption |

5~50Kg/T oil |

|

Waste bleaching earth oil content |

<35% |

|

Deodorization loss consumption |

≤0.5% |

Refining Processes:

- Decolour tank is for bleaching grease.

- Deodorizing tank is for desdorizing grease(stainless steel).

- Conducting oil furnace provide thermal enery need for production, the temperature reach to 280degree.

- Vacuum pump provides vacuum for bleaching, deodorization which can reach 755mmHg or more;

- Air compreassor can dry the bleached clay

- Air press is for filter clay

- Steam generator can generate steam distillation required.

- This kind of oil refining eqiupment make the oi reach the standard level national edible oil.

Flow Chart :

Main parts : De-mixed, degumming, dehydration, deacidification, decolorzation, dewaxing and deodorization.

Characters:

Safety:

1. we using auto welding machine to make the reactor,which can quarrantee the quality of welding seam,avoid cracking and has a long life for about 8 years.

2. professional heating treatment and x-ray detection chamber for welding seam .

3. vacuum system to prevent oil gas be back to reactor causing accident.

4. with professional thermometer , professiona pressure gauge and safety valve.

Environment friendly:

1.dedusting system to prevent gas and dust from coal burning

2.the exhaust gas will be recycled for heating reactor ,no gas pollution

3.well sealing on every junction parts to prevent gas leak,no smelly

Longer life :

Using Q345R special steel plate ,welding seam with auto welding an will get heating treatment and x-ray detection to extend the life of reactor to the most extend, and the life will 8 years

Energy saving:

1. well sealing for heating system ,no gas leak and saving fuel.

2. the exhaust gas will be recycled for reactor heating

Company Information

Why not choose us

a. 30 years manufacturing experience.

b. 60 technical engineers research on new efficient processing craft and instruct manufacturing and installation.

c. 80 technicians-professional installation team with rich and mature installation and training experience.

d.10 senior engineer.

e. CE, ISO9001,BV,etc.

Packaging & Shipping

1.Packed by the protect film inner, water-repellent plastic outside. 2.The wood packing is necessary if send by less than a container. 3.Generally, shipped by high cubic container,such as 20 feet,40 feet.

4.Based On this condition,we should make sure it is in good condition when arrived destination.

5.According to the customer requirement

Certifications

Technical parameters of High Yield Rate Palm Oil Making Machine in Indonesia

| Voltage | 380v |

| Power(W) | Depend on palm kernel oil output |

| Dimension(L*W*H) | Depend on output |

| Weight | Depend on output |

| Certification | ISO9001 |

| After-sales Service Provided | Engineers available to service Machine overseas |

| Item | palm kernel oil machine |

| Application | all kinds of seeds oil extraction |

| solvent extraction consumption | less than 2kg/t |

| Power consumption | less than 15kwh/T |

| Residue oil in cake | less than 1% |

| Output | as your requirement |

| Material | carbon steel, stainless steel |

| Warrenty | 1 year |

| Business type | manufacturer |

| working principle | screw extrusion |