Hot Selling Palm Fruit Thresher in Nigeria

- Usage: edible oil, all kinds of vegetable seeds

- Type: palm oil refinery

- Automatic Grade: Automatic

- Production Capacity: palm oil refinery

- Model Number: palm oil extraction machine, palm oil refinery

Hot Selling Palm Fruit Thresher in Nigeria Description

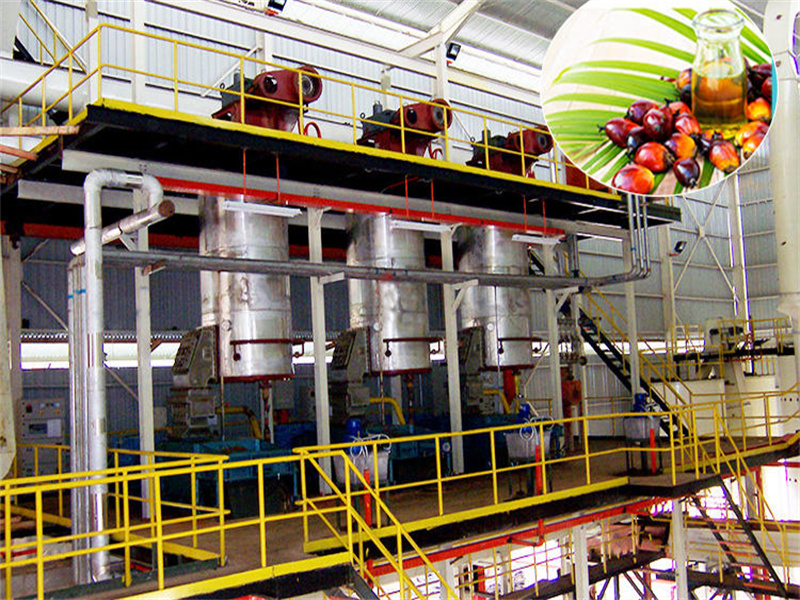

Palm fruit bunch oil process machine

Flowchart of Palm fruit bunch oil process machine

- palm fruit/bunch → sterilization → threshing → digesting → clarification → purification →dring → CPO→ refining → decolorizing → deodorizing →RBD palm oil → crystallization → fractionation → RBD olein & RBD stearin

- palm kernel →depericarper → crushing → pressing → CPKO → refining → RBDPK oil , RBDPK olein & RBDPK stearin

Main Sections of Palm fruit bunch oil process machine

|

|

Main section |

Main machines |

|

|

1 |

Fresh palm fruit bunch reception section |

Loading ramp |

|

|

2 |

Sterilization section |

Sterilization tank |

|

|

3 |

Threshing section |

Threshing Machine c/w Platform |

|

|

4 |

Pressing section |

Screw presser |

|

|

5 |

Oil clarification section |

Clarification Tank |

|

|

6 |

Fiber separation section |

Depericarper Column |

|

|

7 |

Palm kernel recovery section |

Nut sheller |

|

|

8 |

Engine room |

Diesel generator |

|

|

9 |

Boiler house |

Boiler |

Process Steps of Palm fruit bunch oil process machine

1. Bunch reception station of Palm fruit bunch oil process machine

Loading ramp as palm fruit unloading, cleaning, storage platforms, all hydraulic segmented discharge

2. Sterilization station of Palm fruit bunch oil process machine

The use of high temperatures to cook soft fruit bunches and sterilization (145 °C ,90-120 minutes), easy to separate fruit bunches fruit, soft fruit, increasing the humidity of the fruit, 3.Threshing station of Palm fruit bunch oil process machine

Fresh palm fruits separate from bunches by thresher rotary drum rotating. Palm fruits are conveyed to digesting tank by elevator.Empty bunches are conveyed out of factory by scraper conveyor. Thresher shaft uses once forging technology. The equipment is stronger and has longer life. At the same time , our company developes non-shaft thresher drived by chain. in this way, it reduces power loss and saves production cost. 4. Pressing station of Palm fruit bunch oil process machine

The palm fruit oil yield increases by adjusting material moisture and temperature in digesting tank. Digesting tank uses liquid level control, so material can distribute automatically and equipment runs fully automatically. Pressing machine uses hydraulic control system to adjust spacing between pressing bolts. So it can be suitable for various palm fruit species and guarantee the oil yield.

5. Clarification Station of Palm fruit bunch oil process machine

The oil and the sludge taken out separately (by 90% pure oil) is taken out of the oil containing 45% -55% of the water, sludge and other things.

Purification: oil purification process – improving pure

Drying: Continuous Vaccum Drier with the oil out of the water, the water can be reduced to 0.1%.

6. Kernel recovery station of Palm fruit bunch oil process machine

Depericarper (splitter): Through floating dry processing the fruit core and fibers separated.

Fiber and other lighter stuff was blown appearance

Crushing (Crusher): stone cracked open grain separation kernel and shell. In Hydrocyclone, the use of kernel and core-shell particle proportion to their separation.

7. Power House (power house) of Palm fruit bunch oil process machine

the use of diesel powered generators and turbine generators, more environmentally friendly energy production and electricity consumption to power.

8.Water Treatment of Palm fruit bunch oil process machine

After settling, filtration, dosing and other processes to ensure that the water quality, but also to ensure oil quality.

Palm fruit bunch oil process machine :

Our Services

Pre-sales Service

1.Offering comprehensive technical and business consultation services;

2.Proposing the most suitable scheme and equipment for our clients;

3.Designing and fabricating targeted products according to the special requirements of clients;

Service on Sale

1.Providing initiative and enthusiastic service;

2.Introducing & Demonstrating products and its application to clients;

3.Helping clients to choose equipments.

After-sales Service

1.Highly inspecting equipments in every working procedure, quality comes first;

2.Fast & Safe Delivery;

3. Assisting our clients for foundation construction of equipments;

4.Dispatching engineers to install and debug equipments;

Packaging & Shipping Company Information

Customer visit:

FAQ

1. Q: Which kind of materials can be processed?

A: All kinds of oil seeds. For example, rice bran, corn germ, cottonseeds, peanut, sunflower, soybean, rapeseed, etc.

2. Q: What’s the capacity?

A: 5-2000 tons per day.

3. Q: The materials of our machine?

A: The stainless steel and carbon steel.

4. Q: Can you install the machine in local place.

A: We will send our engineers to local place to help installing the machine.

5. Q: How to operate the machines?

A: Our engineers will train the worker how to operate it after running.

If you have interest in our Palm fruit bunch oil process machine,please kindly send us your inquiry details in the Below , Click “Send” Now!

Technical parameters of Hot Selling Palm Fruit Thresher in Nigeria

| Voltage | depend on palm oil extraction machine, depend on the capacity |

| Power(W) | depend on palm oil extraction equipment, depend on the capacity |

| Dimension(L*W*H) | depend on palm oil extraction equipment, depend on the capacity |

| Weight | depend on palm oil extraction equipment |

| Certification | ISO9001 |

| After-sales Service Provided | Engineers available to service Machine overseas, Engineers avto service Machine overseasailable |

| Steam consumption | based on palm oil extraction machine |

| Color | based on palm oil extraction machine |

| Residual oil in meal | Less than 1% |

| Crude oil moisture and volatile matter | Less than 0.30% |