Made in China Palm Kernel Oil Expeller Machine in Philippines

- Usage: palm oil mill Machine

- Type: palm oil mill Machine

- Automatic Grade: Automatic

- Production Capacity: 5-100T/H

- Model Number: MO77

Made in China Palm Kernel Oil Expeller Machine in Philippines Description

Company Information

1. Why is always Doing???

a. 20 years manufacturing experience.

b. 26 technical engineers research on new efficient processing craft and instruct manufacturing and installation.

c. 76 technicians-professional installation team-with rich and mature installation and training experience.

d. CE and ISO9001

2. What’s kind of machine we can manufacture???

Oil seeds press production line: 5-2000T per 24 hrs

Solvent extraction production line: 10-1000T per 24 hrs

Edible oil refinery production line: 1-600T per 24 hrs

Biodiesel production line: 1-600T per 24 hrs

Palm oil processing line:5-240T per 24 hrs

3. What choose Doing for palm oil???

Doing is the real supplier of whole palm oil line. The machine of our palm oil making line is different from other oil seeds. This line is developed by our engineers and specialized for palm oil. If you need process the palm fruit to oil successfully, you must choose Doing.

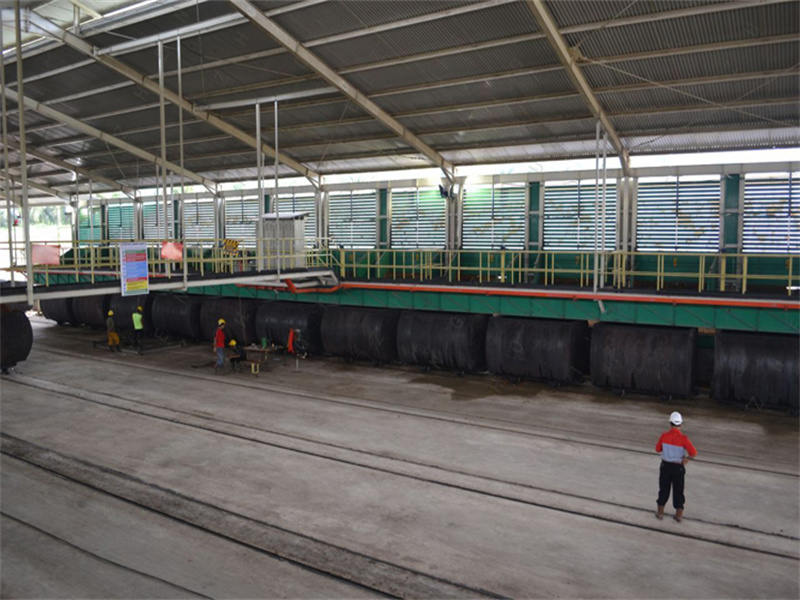

Palm Oil Extraction Machine

The crude oil making section of palm oil extraction machine

1. Raw materials storage section: Fresh palm fruit bunch must be loaded slopes and stored.

2. Sterilizing section: fresh palm fruit bunch are airtight sterilized in sterilizer. 3. Threshing section: The purpose of threshing is to separate the palm fruit from the fruit bunch. 4. Pressing section: This step is used to get the oil from the palm fruit. The presser for palm fruit is different from other materials.

5. Clarification section: Clarification will separate the oil and sediment. Then the oil will be storaged in oil tank, the fiber will be sent to treat pond. 6. Finished oil storage and transportation section: Finished crude oil is stored in storage tanks, serve oil shed loading and issuing regularly oil to outside. Finished crude oil generally be stored and transported between at 32 °C to 40 °C.

7. Fiber separation section: Press cake broken by breaking screw conveyor and then transported into the fiber separation air net and fiber polishing roller for fiber separating. 8. Kernel recovery section: If you want to recycle the palm kernel, this is a necessary step to collect the palm kernel. Then you can use the palm kernel to make palm kernel oil.

9. Sewage treatment section: the waste water has high organic matter content, so it’s need be treated before pour.

The palm oil refinery section of palm oil extraction machine

1. Degumming and deacidification: This part is used to move the gum and acid in the crude palm oil.

2. Decolorization: The color of crude palm oil is red. Then the decolorization part will reduce the red color of crude palm oil. The oil after decolorization will be more clear.

3. Deodorization: The function of this part is to move the bad smell in the crude palm oil.

4. Fractionation: This is the special part for palm oil refinery. This step can separate the stearin and palmitin. They can be used in different fields.

The specification of refined palm oil

|

Item |

Standard |

|

Color (Lovibond Cell 133.4mm) ≤ |

R3.0 Y3.0 |

|

Smell and taste ≤ |

No smell and good taste |

|

Transparence ≤ |

Clear and transparent |

|

Moisture and volatile matter (%) ≤ |

0.03 |

|

Insoluble impurities (%) ≤ |

0.03 |

|

Acid value (mgKOH/g) ≤ |

0.16 |

|

Peroxide value (mmol/kg) ≤ |

10 |

Packaging & Shipping

Delivery of our oil extraction machine:

Each oil extraction machine is well packed by thin films.

Use iron case or iron pallet to fix the machine strongly.

All goods are ensured to arrive on time based on sales order requirements.

Our Services

Our Services

1. Professional solution design, high quality machines, competitive prie.

2. Consult and answer all your questions within 24 hours.

3. Factory layout design according to your requirement.

4. Formulation available.

5. Fast delivery:15 working days for single machine/40 working days for complete line

6. Professional engineer, overseas installation and commissioning, training.

7. Warranty: 1 years

8. Service life long technical support.

FAQ

Some FAQs for our oil extraction machines line:

1. Q: Are you a trading company or a manufacturer ?

A: We are a manufacturer, which has long experience in this industry.

2. Q: How can I get to your company ?

A: You can get a flight to Xinzheng Airport. We are just about 40- 50mins away from Xinzheng Airport.

3. Q: How long is your guarantee ?

A: One year(Calculated from the equipment arrives the customer’s side.). After this period we will definitely support you when needed. You will be welcome to contact us with any problem may happened.

4. Q: Will you send engineers to install the plant?

A: yes, but at an extra cost payable by the customer. Or you can get local contractors to do the commissioning and we send one supervising engineer.

5. Q: Do you have some foreign customers using your equipment?

A: yes, we have our company has established business relationships with customers in Indonesia, German, Slovakia, Ukraine, Vietnam, Pakistan, the Philippines, Indonesia, Thailand, Pakistan, Egypt ,Iraq, Iran,Jordan,Saudi Arabia,Syria, Libya etc.

Technical parameters of Made in China Palm Kernel Oil Expeller Machine in Philippines

| Voltage | 220V/380V/440V |

| Power(W) | 100kw |

| Dimension(L*W*H) | Depend on the capacity |

| Weight | Depend on the capacity |

| Certification | ISO9001/CE/BV |

| After-sales Service Provided | Engineers available to service Machine overseas |

| Raw material | Most of vegetable oil seed |

| Process type | palm oil mill Machine |

| Water cosumption | ≤ 0.5 t/t material |

| Power consumption | ≤ 15 kw*h/t material |

| Steam consumption | ≤ 320 kg/t mateiral |

| Manufacturing experience | mroe than 30 Years |

| Advantage | Energy Saving |

| Solvent consumption | ≤ 3 kg/t material |

| Workshop name | palm oil mill Machine |

| Service | Arrange engineers |