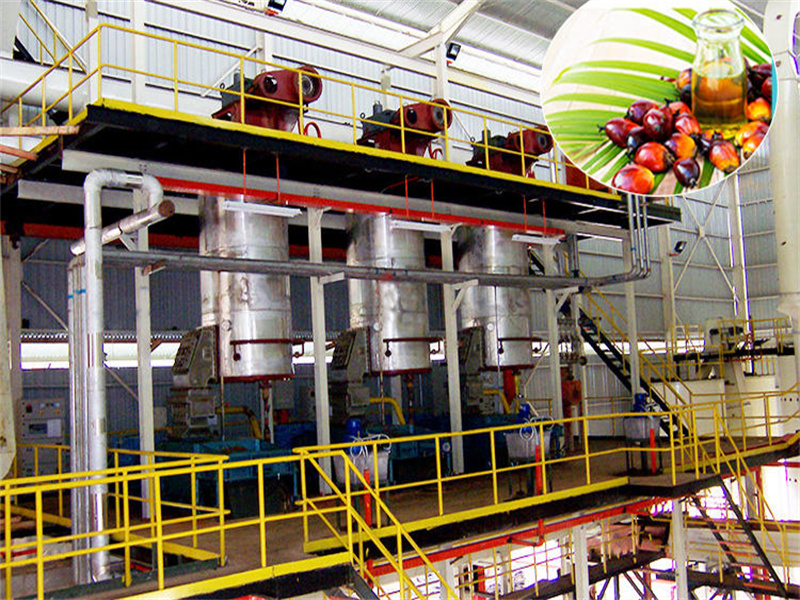

Malaysia Technology 5Ton/Hour Palm Oil Mill Malaysia in Ghana

- Usage: Palm oil press

- Type: palm oil press line

- Automatic Grade: Automatic

- Production Capacity: 100%

- Model Number: edible oil extraction Machine

Malaysia Technology 5Ton/Hour Palm Oil Mill Malaysia in Ghana Description

Malaysia technology 5Ton/hour palm oil mill malaysia

Contact Email: dinter0002 @ dinter.cn

Our Services

1. Write the project feasibility study report

2. Undertake project design including technology, civil engineering, steel structure, Machine, electric, automation

3. Providing professional support for the consultation of engineering technology and technical problem.

4. Optimizing plant design for the existing technology, make the production and business more competitive. The automation reconstruction, intelligence control, stable and safety operation for the existing production line

5. After-sale service, training your labors on basic theoretical knowledge, technology of production processing and operation and maintainenance.

FAQ

Q1 : Which kind of materials can be processed?

All kinds of oil seeds. For example, sunflower seeds, rice bran, corn germ, palm fruit, palm kernel,coconut,peanut, soybean, sesame, cottonseeds, rapeseed, etc.

Q2 : What’s the capacity?

Generally, 10-5000 tons per day. We can also manufacture as per customers’ requirements.

Q3 : How long is the warranty?

The main parts of the machine come with one year warranty and after the expiration our engineer is available overseas to do the maintenance work.

Q4 : Can the machine be installed locally?

We can do the turn-key projects or other services according to customers’requirements,according to this condition,our services can be manufacturing,purchasing,transporting,installation,training labors etc.

Q5 : How to operate the machine?

Our engineers will be available to guide and train your labors how to operate and run the machine.

Business Scope

Content of engineering: process design, general contract engineering for mechanical & electrical equipment construction and installation & debugging.

1. 10-5000T/D Oilseed preliminary cleaning, drying, storage section turn-key project

2. 5-5000T/D Oilseed pretreatment & pre-pressing production line turn-key project

3. 100-5000T/D Oilseed extraction production line turn-key project

4. 5-3000T/D Physical (Chemical) refining, fractionation production line turn-key project

5. 10-3000T/D Cold pressed peanut synchronization extraction protein powder under low temperature turn-key project

6. 10-1000T/D Phospholipid concentrate production line turn-key project

7. 10-500T/D Animal oil boil, refining, shortening and margarine turn-key project

8. 10-500T/D Biodiesel production line turn-key project

9. 10-1500T/D Cottonseed husking project

10. 10-3000T/D Sunflower oil, rice bran oil, corn germ oil pressing, refining, dewaxing turn-key project

11. 1-100T/D Peony seed oil, tea seed oil, ect. turn-key project

12. 10-2000T/D Full automatic control filling packing production line turn-key project.

1. Palm Oil Mill Plant —Palm Fruit Reception Station

The FFB of palm oil machine gets into the factory through the weighbridge to weight the raw materials to calculate the production cost. Palm bunch reception process is finished at loading ramp. This loading ramp makes palm fruit unloading, cleaning, storage platforms, adopting all hydraulic segmented discharge. 2. Palm Oil Mill Plant —Sterilizing Station

The FFB of palm oil processing machine are discharged into the loading ramp, then transported to sterilizer for sterilization. It uses high temperature to softening the fruit and kill the bacteria, this will increase the moisture content of fruit and separate the fruits easily, so finally it will easy to get oil and separate palm kernel, also avoid the raising of free fatty acid. From picking to sterilization, the time shall not over 24 hours.

3. Palm Oil Mill Plant —-Threshing Station of Palm Oil Machine

In the sterilizing process of palm oil mill, the palm fruits are softening, through the threshing and screening of thresher to separate the palm fruits and empty fruit bunches(EFB).

4. Palm Oil Mill Plant —Empty Bunch Treatment Station

The EFB are stored to be use as fuel or fertilizer, also can be used for other functions.

5. Palm Oil Mill Plant —-Pressing Station of Palm Oil Processing Machine:

Transport the palm fruits to the digester to mixed and cooked again to separate the palm pulp and nut, then use double screw hydraulic presser to get crude palm oil, which improved the production efficiency greatly.

6. Palm Oil Mill Plant —Clarification Station

The pressed CPO of palm oil mill has some water(about 45%-55%) and other impurities, we need to clarify the CPO into dirty oil and clean oil. The clean oil will be dried then transported to crude oil tank, while the dirty oil will through centrifuge for recovery.

7. Palm Oil Mill Plant —Oil Tank and Oil Loading Shed

Store the crude palm oil and ready to load the oil to other places. 8. Palm Oil Mill Plant —Depericarping Station of Palm Oil Machine

The pressed palm fiber cake gets into the cake breaker then get into the winnowing system to separate the fiber and nut.

9. Palm Oil Mill Plant –Kernel Recovery System

Then nut will be crushed to get shell and kernel. Through winnowing system and washing system to separate the shell and kernel. The shell can be used as fuel for boiler, the kernel will be dried for storage.

10. Palm Oil Mill Plant —Boiler House of Palm Oil Processing Machine

In the whole production process, it will need much steam to cooking and softening the palm fruits. The boiler has features of high heat efficiency, reliable working, high over-load capacity, wide application, etc.

11. Palm Oil Mill Plant —Power House of Palm Oil Machine:

Adopts diesel engine generator and steam-turbine generator to provide power to production and life using electricity.

12. Palm Oil Mill Plant —Water Supply and Treatment (Including boiler water treatment)

Through the processes of settling, filtration, medicals feeding, to ensure the quality of water, and also the quality of oil.

13. Palm Oil Mill Plant —Effluent Treatment Plant

The effluent has high content organic matters, BOD (biochemical oxygen demand) is about 25000PPM, it needs to be processed into qualified water then can discharge. Now the impounding reservoir effluent processing system is the most using and effective method. This kind processing system of palm oil mill is very economic.

Packaging & Shipping

Palm Oil Mill Plant can be packed in wooden case, several 40ft containers, and bulk shipping.

Technical parameters of Malaysia Technology 5Ton/Hour Palm Oil Mill Malaysia in Ghana

| Voltage | 380V |

| Power(W) | according to capacity |

| Dimension(L*W*H) | various with capacity |

| Weight | various with capacity |

| Certification | ISO CE BV |

| After-sales Service Provided | Engineers available to service Machine overseas |

| Raw material | oil seeds |

| Product | to make crude edible or refined edible oil |

| Solvent name | n-hexane |

| Capacity | from 5T to 2000T edible oil extraction |

| Oil residues | less than 1% |

| Manufacturing experience | 20 years experience in edible oil field |