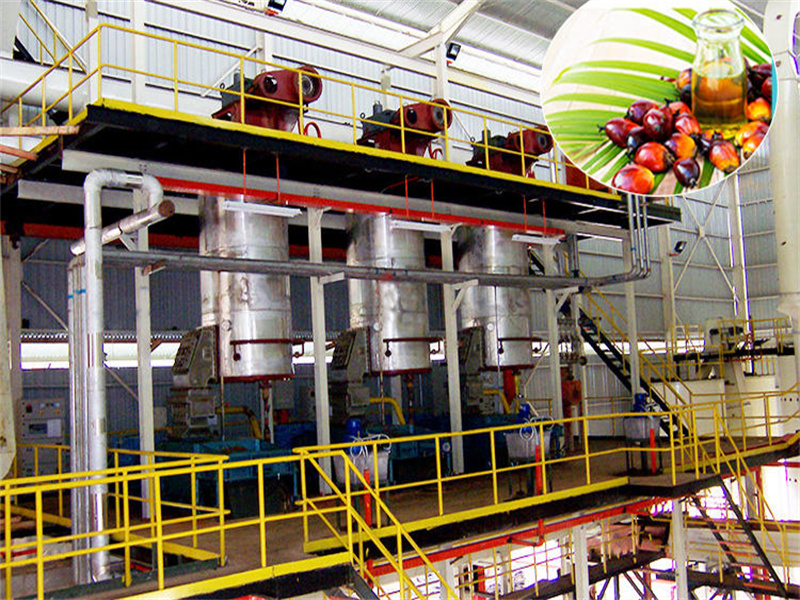

Palm Fruit Oil Mill/Palm Fruit Oil Processing Machine in Nigeria

- Usage: vegetable oil refinery equipment

- Type: vegetable oil refinery equipment

- Automatic Grade: Automatic

- Production Capacity: 100%

- Model Number: palm oil refine Machine

Palm Fruit Oil Mill/Palm Fruit Oil Processing Machine in Nigeria Description

High quality palm oil mill malaysia with best price

Palm oil mill malaysia Process Flow Chart EFB(Empty Fruit Bunch)

↑

FFB(Fresh Fruit Bunch)→Loading →Sterilizing →Threshing →Press →Oil Clarify →CPO

↓

Fiber Separation →Fiber

↓

Kernel Recovery →Shell

↓

Palm Kernel

↓

Press →Kernel cake

↓

PKO(Palm Kernel Oil)

Parameter of Palm oil mill malaysia

| Oil content in FFB | ≥ 24 % | Oil extraction rate | 22~23% |

| Shell content in FFB | ≥ 6~7% | Kernel content in FFB | 4% |

| Empty bunch content in FFB | 23% | Fiber content in FFB | 12~15% |

| Oil content in empty bunch | 5% | Press cake proportion in FFB | 24% |

| Solid phase in empty bunch | 32% | Moisture in empty bunch | 63% |

| Water content in press cake | 40% | Oil content in press cake | 6% |

| Oil content in nut | 0.08% | Solid phase in press cake | 54% |

| Oil content on meter solid | 3.5% | Oil content in wet meter heavy phase | 1% |

| Fruit in empty bunch | 0.05% | Oil content in final effluent | 0.6% |

| Kernel in empty bunches | 0.05% | Water in palm kernel | ≤7% |

| Kernel content in LTDS | 0.15% | Kernel content in cyclone fiber | 0.15% |

| Kernel content in wet shell | 2.5% | Kernel content in dry shell | 2% |

Main Parts of Palm oil mill malaysia

Reception Station of Palm oil mill malaysia

Fresh Fruit Bunch (FFB) is transported by trucks, and get into the palm oil factory through the weightbridge to weight the raw materials to calculate the production cost. Palm bunch reception process is finished at loading ramp. This loading ramp makes palm fruit unloading,cleaning, storage platforms, adopting all hydraulic segmented discharge.

Sterilizer Station of Palm oil mill malaysia

Fresh Fruit Bunch(FFB) is conveyed to horizontal sterilizer or vertical sterilizer, and 3 bar saturated steam is pumped into sterilizer for sterilization purpose, making the fruit soft and increasing its moisture. The sterilization process need to be 90-120 mins in order to make fruit and empty bunch separated easily, also make oil extraction easily.

Thresher Station of Palm oil mill malaysia After the sterilization, the palm fruit is transported into thresher by elevator conveyor, palm fruit and empty bunch are separated by viberating process, after this, palm fruit is conveyed into cooking pot, and empty bunch can be usd as fuel or fertilizer.

Clarification Station of Palm oil mill malaysia

The crude palm oil (CPO) after pressing has water and impurities, so we need to clarify CPO to dirty oil and clean oil, clean oil will be transported in crude oil storage tank, while dirty oil will be recovered by centrifuge.

Do you want more informtaion about Plam Oil Press Machine?

Please contact me without hesitation!!!

Technical parameters of Palm Fruit Oil Mill/Palm Fruit Oil Processing Machine in Nigeria

| Voltage | 380V 410V |

| Power(W) | crude oil refinery machine |

| Dimension(L*W*H) | crude oil refinery machine |

| Weight | crude oil refinery machine |

| Certification | CE and ISO |

| After-sales Service Provided | Engineers available to service Machine overseas |

| Function | vegetable oil refinery equipment |

| Warranty | 12 months |

| Raw material | crude mustard oil |

| final product | refined mustard oil |

| texture | stainless steel or carbon steel |

| coclor | according to customer |

| capcity | 1-4000TPD |

| service after sale | workshop design/installation |

| service life | 60 years |

| others | according to customer |