Palm Fruit Red Oil Machine With Single And Double Screw

- Usage: Malaysia/Indoneisa/Nigeria

- Type: palm oil mill processing

- Automatic Grade: Automatic

- Production Capacity: 10-80T/H

- Model Number: FL80

Palm Fruit Red Oil Machine With Single And Double Screw Description

Alibaba golded supplier best automatic palm oil processing machine

Compay profile

Our Company: Zhengzhou Qie Grain and Oil Machine Co.,Ltd.

Zhengzhou QI’E Grain And Oil Machine Co.,Ltd. Is specialized in researching and developing in palm fruit oil plant, palm oil refinery plant, layout design and equipment design, we can also provide strong technical support. With our development in palm oil process field, our company can offer advanced technology and our market expand to Malaysia and Indonesia and Africa, Our company can offer turn-key project, old palm oil mill update or reconstruction, we can offer abroad engineering service.

a. Why choose Zhengzhou Qie Grain and Oil Machine Co.,Ltd. ?

1.Our company has been set up since 1982, It has been awarded the “The quality-star enterprise of China”, we have more than 30-yeat history in the manufacturing of oil machine.

2.Our factoru is also a group enterprise integrating scientific research, manufacturing, sales as one.

3.We have cooperated with Research Institute of Machine Design Company and Henan, Henan University of Technology (formerly the Zhengzhou Grain College) school-enterprise cooperation in the oil equipment to carry out long-term, protein extraction, phospholipid extraction, etc. R & D and application of new technologies.

4.We have more than 200 employees ,among them ,there are 20 engineering technical personnel who hold intermediate and senior professional titles, and two highly reputed professors.

5.We have exported our machines to Moscow, Romania, Pakistan, India, Bangladesh, Thailand, Indonesia, Nigeria, Malaysia, Tunisia, and so on. Our new customers can visit our demo machines in different countries.

b. What can we supply to our customers?

1. 1TPH Palm fresh fruit bunch(FFB) Press project equipment manufacture,installation and Turnkey project;

2. 2TPH-10TPH Palm fresh fruit bunch(FFB) Press project equipment manufacture,installation and Turnkey project;

3. 15TPH-30TPH Palm fresh fruit bunch(FFB) Press project equipment manufacture,installation and Turnkey project;

4. 40TPH-80TPH Palm fresh fruit bunch(FFB) Press project equipment manufacture,installation and Turnkey project;

5. 5TPD-500TPD Palm oil refinery project production;

6. 5TPD-500TPD Palm oil fractionation project production;

7. Equipment spare part supply;

8. Project design and technology support.

c. Our turning-lathe

Palm Fruit Oil

Palm tree grows in Southeast Asia, Africa, south pacific, and some tropical area in South America. It originated in Africa, was introduced to Southeast Asia in the early 19th century. The wild and half wild palm tree in Africa called dura, and the by breeding, develop a kind named tenera with high oil yield and thin shell. From the 60s last century, almost all the Commercialized palm tree is tenera. Palm fruit can be harvested throughout the year.

Palm Fruit Process — automatic palm oil processing machine

FFB reception station→ Sterilization station → Threshing station → Digesting station→Pressing station→Crude palm oil(CPO)

↓

Nut drying← Kernel crushing ← Kernel&Fiber separation ←Crushing ←Palm cake

↓

Nut oil pressing →Filteration→Crude palm kernel oil(CKO)

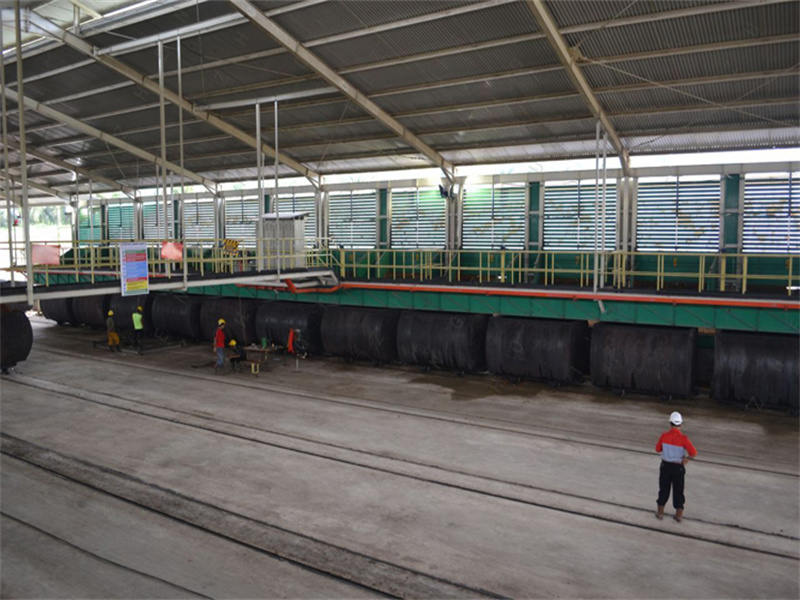

a. Reception station — automatic palm oil processing machine

Palm fruit oil mill Reception is used for loading the Fresh fruit bunch (FFB) to the palm fruit cage. Adopt hydraulic control system. as our experience, some palm oil pant use concrete structure, but it’s not good for cleaning. Now we adopt steel material, fence structure. Some impurity will drop down to a conveyor, impurity will conveyed to outside. Easy for cleaning.

2. Vertical Sterilizer — automatic palm oil processing machine

FFB transported by scraper conveyer fall into sterilizing tank, make FFB soft,get more oil yield. sterilizing time 90~120mins, temperature 130~145℃.Sterilizer can be design as owner’s requirement.horizontal sterilizer or vertical sterilizer for our customer.

3. Horizontal Sterilizer — automatic palm oil processing machine

For big scale palm oil mill, we adopt horizontal sterilizer, can produce continued increase the effective.

Sterilizing station adopt high quality material, have characteristics of long time life , Low failure rate, easy maintain, etc.

4. Thresher Station — automatic palm oil processing machine

Palm fruit thresher in palm oil plant is used for separate empty fruit bunch and palm fruit.According the palm oil mill capacity we can design the thresher capacity, usually we have a spare one, in case one of them not work. Empty fruit bunch from thresher will be conveyed to outside, can be used as fertilizer in palm fruit plantation. Sterilized palm fruit will be convey to next station.In the threshing station, we adopt stell structure, easy clean, easy operate, easy maintain.

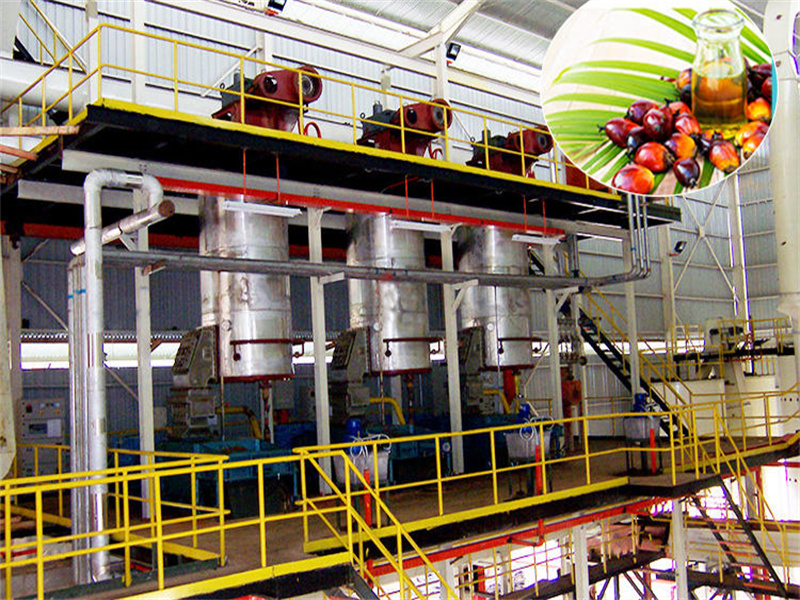

5. Press Station — automatic palm oil processing machine

Pressing station in palm oil plant is include digestor and oil presser.

Sterilized palm fruit from thresher conveyed to digestor. There are blades in digestor, blades will be rolling by motor which is on the top of digestor. Palm fruit peel can be crushed by blades, besides we will fill the steam in digestor for heating. Palm fruit pulp cell can be destroyed under the high temperature condition, after that we can get higher oil yield.

6. Screening filter — automatic palm oil processing machine

Clarification in the palm oil station. For crude oil clean, we use screening filter and Decanter Centrifuge to remove the impurity in the crude oil. After process the impurity in the oil can get storage standard

7. Decanter Centrifuge — automatic palm oil processing machine

Clarification in the palm oil station. For crude oil clean, we use screening filter and Decanter Centrifuge to remove the impurity in the crude oil. After process the impurity in the oil can get storage standard

The processing technology parameter of automatic palm oil processing machine

|

Capacity : |

Oil extraction rates : |

22~23% |

||

|

Oil content in FFB : |

≥24% |

Kernel content in FFB: |

6.5% |

|

|

Shell content in FFB : |

≥6~7% |

Fiber content in FFB : |

12~15% |

|

|

Empty bunch content in FFB: |

23% |

Press cake proportion in FFB: |

24 % |

|

|

Oil content in empty bunch: |

5 % |

Moisture in empty bunch : |

63 % |

|

|

Solid phase in empty bunch: |

32% |

Oil content in press cake: |

6 % |

|

|

Water content in press cake : |

40 % |

Solid phase in press cake : |

54 % |

|

|

Oil content in nut: |

0.08% |

Oil content in wet meter heavy phase |

1% |

|

|

Oil content on meter solid: |

3.5% |

Oil content in final effluent: |

0.6% |

|

|

Fruit in empty bunch: |

0.05% |

Water in palm kernel |

≤7% |

|

|

Kernel in empty bunches: |

0.05% |

Kernel content in cyclone fiber: |

0.15% |

|

|

Kernel content in LTDS: |

0.15% |

Kernel content in dry shell: |

2% |

|

|

Kernel content in wet shell: |

2.5% |

Certifications

Visting and Delivery

My contact

Interested in our machine? Pls writing your requirements in the follow dialog, then send me! Bruce is waiting for u.

Technical parameters of Palm Fruit Red Oil Machine With Single And Double Screw

| Voltage | OL90 |

| Power(W) | As per capacity of oil refinery |

| Dimension(L*W*H) | As per capacity of oil refinery |

| Weight | As per capacity of oil refinery |

| Certification | ISO9001, CE, BV |

| After-sales Service Provided | Engineers available to service Machine overseas |

| Refined oil quality | 1st, 2nd, 3rd, 4th refined oil |

| Phosphoric acid | 2~3kg/T oil |

| Waste bleaching earth oil content | <35% |

| Electric consumption | 28kwh/T oil |

| Deodorization loss consumption | ≤0.5% |

| Crude oil | Vegetable oil |

| Steam consumption | 450kg/T oil |

| Bleaching earth consumption | 5~50Kg/Toil |

| Circulating water cooling water yield | 150m³/H |

| cooling water | 13~28℃ |