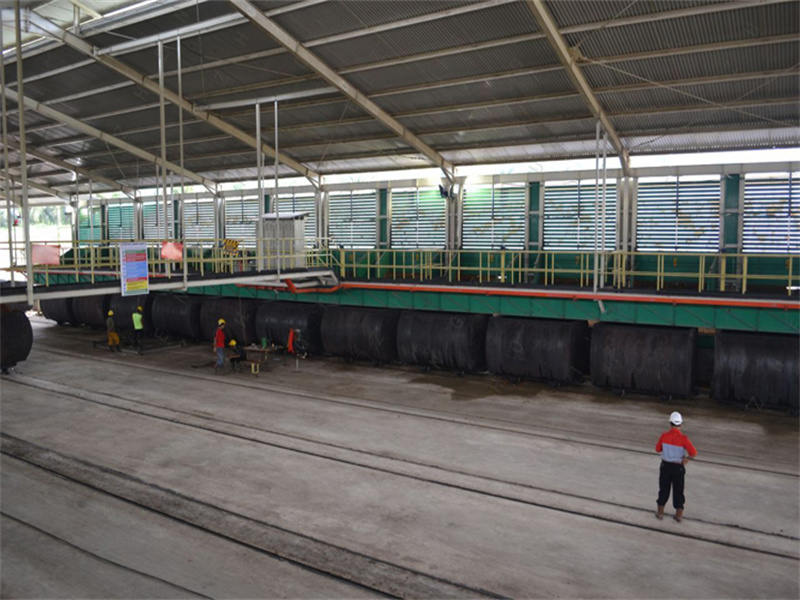

Palm Kernel Cake Oil Solvent Extractor Equipment in Malaysia

- Usage: Palm Oil

- Type: Cold & Hot Pressing Machine, Palm Oil Refinery Plant

- Automatic Grade: Automatic

- Production Capacity: 30TPD Palm Oil Refinery Plant

- Model Number: QIE-185 Palm Oil Refinery Plant

Palm Kernel Cake Oil Solvent Extractor Equipment in Malaysia Description

5—200TPD Mustard/Soybean/Palm Kernel Oil Refining Machine

Company Information

Brief Introduction

QIE Machinery is a professional modern enterprise which specialized in manufacturing cooking oil machines for various oilsees crops for many years with rich experience, including both small scale cooking oil production line and large scale cooking oil production line. We can realize total turn-key project from design to installation and commissioning. Our products have obtained certificates of ISO9001:2000, ISO14001 and CE .

WHAT CAN WE SUPPLY FOR OUR CUSTOMERS?

1. 10-500T/H oil material first cleaning,drying and storage section turn-key project.

2. 100-3000 T/D oil pretreatment, shelling and pre-press workshop turnkey project (soybean hot peeling, bean skin crushing; the soybean extrusion, high oil contained pre-press cake extrusion, and high oil contained embryos puffed; of direct puffed).

3. Rice bran production line turn-key project.

4. Leaching workshop turnkey project (Towline extractor, Rotocel extractor, loop type extractor, DTDC separated machine, the full negative pressure evaporation, paraffin wax recovery, leaching workshop degum, phospholipid concentrate).

5. Leaching workshop turnkey project (Towline extractor, Rotocel extractor, loop type extractor, DTDC separated machine, the full negative pressure evaporation, paraffin wax recovery, leaching workshop degum, phospholipid concentrate).

6. 30-1000T/D oil continuous grade two or one physical (chemical) refining production line.

7. 10-600T/D sunflower oil, rice bran oil, corn germ oil dewaxing turn-key project.

8. 10-200T/D Fatty acid esterification production cooking oil production line.

Our Services About 5—200TPD Mustard/Soybean/Palm Kernel Oil Refining Machine

1.Pre-sale services:

1) Selecting equipment type.

2) Designing and fabricating the products in accordance with the special requirements of the clients.

3) Training technical personnel for our clients.

4) Providing construction and technology consultations or working out proper construction schemes for those new, special or difficult projects.

2.Services provided during the sale:

Respect our clients; present the clients with ease, relaxation and a surprise; devote ourselves to improve the total value of our clients.

1) Checking products acceptance ahead of delivery.

2) Introducing the service system to our clients.

3. After-sale services:

Improve the added value of our products, and let the clients free from the using troubles:

1) Assisting the clients preparing for the first construction scheme.

2) Installing and testing the equipments.

3) Training the first-line operators on site.

HonorsCustomer visit

5—200TPD Mustard/Soybean/Palm Kernel Oil Refining Machine

5—200TPD Mustard/Soybean/Palm Kernel Oil Refining Flow Chart

5—200TPD Mustard/Soybean/Palm Kernel Oil Refining Machine

Degumming

Impurity of extracted crude oil must be removed in order to reduce losses and increase yield of oil in oil refining process. Crude oil filter can remove impurities, control impurity of extracted crude oil under 0.2%, thus improve degumming efficiency.

Deacidification

The crude oil is output by the oil feed pump from the oil tank, and next enters the crude oil heat exchanger to recover part of heat after metering and then is heated to the required temperature by the heater. After that, the oil is mixed with the metered phosphoric acid or citric acid from phosphate tank in the gas mixture (M401), and then enters the conditioning tank (R401) to make the non-hydratable phospholipids in oil change into the hydratable phospholipids. Add the alkali for neutralization, and the alkali quantity and alkali solution concentration depend on the quality of the crude oil. Through the heater, the neutralized oil is heated to the temperature (90℃) suitable for centrifugal separation to remove the phospholipids, FFA and other impurities in the crude oil. Then the oil goes to the washing process. Bleaching

Heat degummed oil to 25 ~ 135 ℃, dehydrated into a vacuum dryer 20 ~ 30 min. Moisture of dehydrated oil is less than 0.1% (after degumming of crude oil via the oil contained in the 0.3% to 0.5 % of the water will affect the adsorption capacity of bleaching clay section). Degumming of oil can remove grease in oil pigment to improve oil color, adsorption of aflatoxin and trace metals, phospholipids, other gum and other impurities. It ensures high quality of oil and improves oil stability.

Deodorization

Control oil temperature to 250 ~ 270 ℃ when decolorized oil enters into deodorizer, in direct steam injection, the free fatty acids, ketones, aldehydes and other impurities are removed from the oil, the thermal decolorized action also occurs, and the pigment composition is cleaved distilled from the oil. Deodorized vacuum (absolute pressure) controlled at 266 Pa, the deodorization time is about 2h.

Automatic Control System

Our company has applied the automatic control system with advancedness, security, reliability into the pretreatment, extraction, refining and fractionation in large oil plants. For its application in automatic control system, it can control the production in the entire workshop and monitor the operational status of each device by controlling the computer terminals in the room. Only One person can operate the entire workshop, with efficient production management. It has reduced the production cost greatly and improved the management efficiency.

Our Business Diagram

Advantage Of 5—200TPD Mustard/Soybean/Palm Kernel Oil Refining Machine

1.By combining several years’ practical experience, adopting a kind of unique degumming technology, extending the phosphoric acid and oil reaction time and adding specific additives, our equipment can remove phospholipids in oil to the maximum.

2.The new clay automatic quantitative system can produce more reliable oil of good quality, with less investment for the full vacuum closed refining technology.

3.We can design the optimum refining scheme according to different oils and different requirements for products.

Consumption In 5—200TPD Mustard/Soybean/Palm Kernel Oil Refining Machine

| Steam consumption | ≤ 300Kg/T oil |

| Bleaching earth | 1-3Kg/T oil |

| Power consumption | ≤ 22KWH/T oil |

| Fuel consumption | 10-20Kg/T oil |

| Oil content in bleaching earth | ≤ 23% |

| Phosphoric consumption | 0.5-1Kg/T oil |

| Soft water consumption |

≤ 160Kg/H |

FAQ

FAQ About 5—200TPD Mustard/Soybean/Palm Kernel Oil Refining Machine

Q1: How is the quality of your oil refining machine?

A1: Our oil refining machine are manufactured strictly according to national and international standard, and we take a test on every equipment before being delivered out. We have got CE certification and all kinds of testing report; if you want please just ask us for it.

Q2: What is the warranty for the oil press machine?

A2: Our products have the high quality, we can offer 12 months warranty. The time for the warranty is much longer than any other similar products.

Q3: Can you manufacture the special products according to customers?

A3: Of course the answer is YES. You can contact with us directly.

Q4: How can costumers be sure they can get the products on time?

A4: If we can not deliver the products during the ordered time, we can give back 100% your money. The third part, SGS can also help you check the machine before the delivery.

Q5: Can engineer go to installing and trainig?

A5: The answer is YES YES YES .

Q6: How long is the warranty period?

A6: 18 Months from the oil refining machine arrived at your local date or 12 months after final acceptance, which ever comes first.

Contact Us

5—200TPD Mustard/Soybean/Palm Kernel Oil Refining Machine

Technical parameters of Palm Kernel Cake Oil Solvent Extractor Equipment in Malaysia

| Voltage | 380V |

| Power(W) | Based on Palm Oil Refinery Plant capacity |

| Dimension(L*W*H) | Based on Palm Oil Refinery Plant capacity |

| Weight | Based on Palm Oil Refinery Plant capacity |

| Certification | CE,BV,ISO9001 |

| After-sales Service Provided | Engineers available to service Machine overseas |

| Process | Prepress, Extraction,Refining |

| Refining Process | Degumming,Deacidification,Deordorization,Decolorization,Dewaxing,etc |

| Material | Stainless,Carbonless Steel |

| Oil Quality | Equals to EU Standard |

| Raw Material | Rapeseed,Palm Kernel,Sunflower,Cotton,Soybean,Peanut,Rice Bran,etc |