Palm Oil Extraction Machine Price Small Palm Oil Refinery Machine

- Usage: palm oil refining and fractionation line

- Type: palm oil refining and fractionation line

- Automatic Grade: Automatic

- Production Capacity: 30kg-30t/day

- Model Number: oil press machine for sale

Palm Oil Extraction Machine Price Small Palm Oil Refinery Machine Description

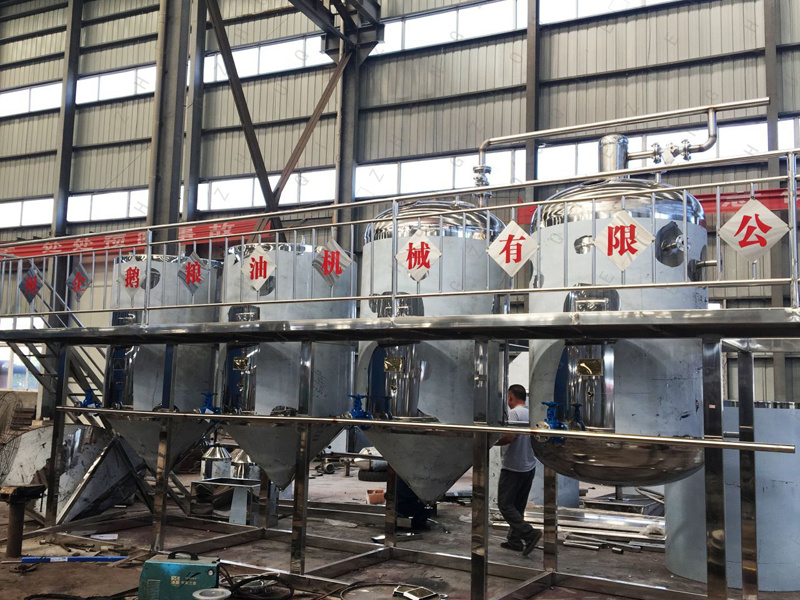

Continuous type crude palm kernel oil refinery machine with low price

Flowchart:

Main Processes :

(1)Degumming process

The purpose of degumming is to remove the phospholipid, sugar, protein, trace mental, and some other impurities, which have bad effect on the stability of the oil. First, the oil

should be heated to 90-105°C, then put some phosphoric into it and stir. It mainly transfer the phospholipid to that can be compatible with water. Then add some salt water to gather the impurities, which subside to the bottom and be discharged. Deacidification:Add some certain quantity of alkali to neutralize the free fatty acids. During this process, some soapstock will be produced.The soapstock will be separated from the oil after using the centrifugal machine.

(2)Decolorization

Mix the oil with activated clay in the oil soil mixing tank, and 1 ton oil needs 5kg clay. Then stir it 10 minutes at 10°C. Next, pump the mixed oil into the decolorization tower. It use steam to heat the mixed oil at 100°C, and the process lasts 30-40 minutes.

Filter:The filter capacity can reach 200meshes. First, we use the filter to remove the clay in the oil, then use the bad filter to purify the oil again. The diameter of the filtering can reach 5μm.

(3)Deodorization The main purpose of deordorization tower is to remove fatty acid and some odor material. The principle of the deordorization is to use the high temperature and vacuum to remove the odor. The fatty acid and odor will be stalled in the storage tank.

(4)Automatic Control System

Our company has applied the automatic control system with advancedness, security, reliability

into the pretreatment, extraction, refining and fractionation in large oil plants. For its application in automatic control system, it can control the production in the entire workshop and monitor the operational status of each device by controlling the computer terminals in the room. One person only can operate the entire workshop, with efficient production management. It has reduced the production cost greatly and improved the management efficiency.

Advantage:

1.By combining several years’ practical experience, adopting a kind of unique deguming technology, extending the phosphoric acid and oil reaction time and adding specific additives, our equipment can remove phospholipids in oil to the maximum. 2.The new carclazyte automatic quantitative system can produce more reliable oil of good quality, with less investment for the full vacuum closed refining technology.

3.We can design the optimum refining scheme according to different oils and different requirements for products.

Energy cosumption:

|

Steam consumption |

≤ 300Kg/T oil |

|

Bleaching earth |

1-3Kg/T oil |

|

Power consumption |

≤ 22KWH/T oil |

|

Fuel consumption |

10-20Kg/T oil |

|

Oil content in waste white clay |

≤ 23% |

|

Phosphoric consumption |

0.5-1Kg/T oil |

|

Soft water consumption |

≤ 160Kg/H |

Company Information

Zhengzhou Qi’E Grain&Oil Machine Co.,Ltd has applied the automatic control system with advancedness, security, reliability into the pretreatment, extraction, refining and fractionation in large oil plants. For its application in automatic control system, it can control the production in the entire workshop and monitor the operational status of each device by controlling the computer terminals in the room. One person only can operate the entire workshop, with efficient production management. It has reduced the production cost greatly and improved the management efficiency.

Certifications

Packaging & ShippingCustomer evaluation

1. The Zhengzhou Qi’e grain and oil Machine company’s experts guide installation and have good technology.

We make the cooperation with Qi’e group many times. Their experts guide installation on-site and after-sales team provides 24 hours of technical services.

I think they have done a well in this respect. Among the large number of grease equipment manufacturers, they are very good in China. Hope we can continue to cooperate in the future.

2. Zhengzhou Qi’e grain and oil Machine company’s equipment have good quality, and shipped on time.

We make the cooperation with Qi’e group for long time. Because they are manufacturer, their equipment have good quality assurance and reasonable price. They shipped on time after we finish contract.

Contact me

Technical parameters of Palm Oil Extraction Machine Price Small Palm Oil Refinery Machine

| Voltage | 380V or designed by your needs |

| Power(W) | Depend on the machine you choose |

| Dimension(L*W*H) | Depend on the machine you choose |

| Weight | Depend on the machine you choose |

| Certification | CE and ISO |

| After-sales Service Provided | Engineers available to service Machine overseas |

| Item | Palm oil refining machine/palm oil fractionation machine |

| Supplier type | Manufacturer |

| Manufacturing experience | 19 years |

| Steel type | MiId steel and SS |

| Raw materials | small scale palm oil refining Machine |

| Fina product | Salad oil |

| Processing method | Machanical press |

| Handling capacity | according to custoemer design |

| Model type | Continuous |

| Main market | Africa, Aisa |