Palm Oil Making Machine Palm Oil Processing Machine in Cameroon

- Usage: Extraction oil from various raw material seeds

- Type: Oil extraction

- Automatic Grade: Automatic

- Production Capacity: 100%

- Model Number: DT

Palm Oil Making Machine Palm Oil Processing Machine in Cameroon Description

Palm fruit threshing machine

Palm fruit threshing machine uses strong vibration to make separation of palm fruit from palm bunches. Raw materials after sterilization are sent to bucket elevator through damp car, and elevated into threshing machine. Palm fruit separates from bunches, sent to next section elevator through screw conveyor. Empty bunches through conveyor and charger, are transported to certain place for further treatment by car.

Palm fruit threshing station can vibrate palm fruit from palm bunches efficiently. It makes further preparation for next step palm fruit oil press processing.

Palm fruit bunches crushing machine

The palm is a kind of important oil crops and Palm oil production is an important industry in Southeast Asia and South America. Empty fruit bunches become a kind of waste after the palm fruit separate from bunches. More than one thousand tons of EFB are produced.

Currently, most of the palm fruit bunches are discarded directly into the palm garden as fertilizer,the other can be used as fuel,but burning will bring great environmental pollution. At the same time it is also a waste of resource.

Recent studies have shown that EFB contains abundant vascular bundle which is very flexible and low density. So the EFB can be used for making paper.We offer palm fruit bunches crushing machine for you to handle palm empty fruit bunches. This equipment uses double roller mesh shear and meshing blade with special shape to achieve the effect of crushing.

Empty fruit bunches crushing machine is the ideal machine of palm bunches processing plant.It makes full use of waste resources–Empty palm fruit bunches,greatly increase the added value, and has made a positive contribution to the world environmental protection. The product has been widely used in Southeast Asia and South America, and the market demand is very big.

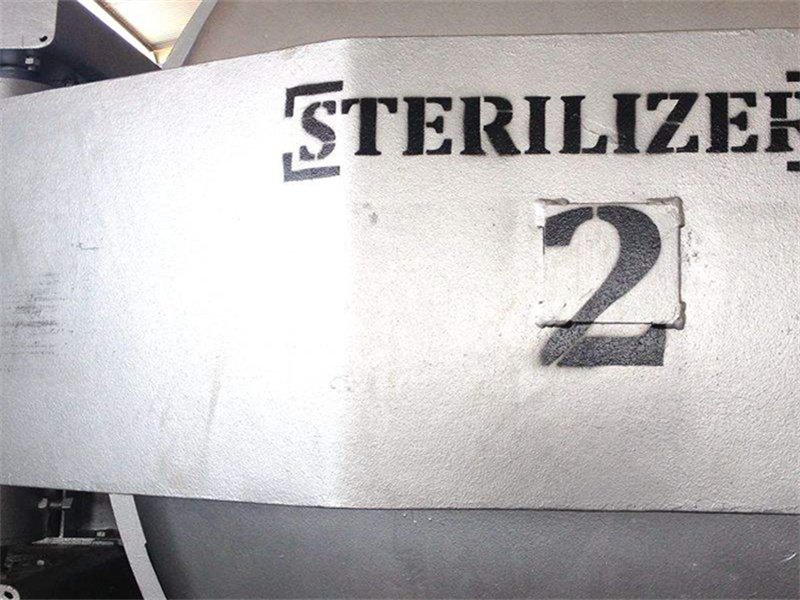

Sterilizer for palm oil mill and cooker for vegetable oil

There are two main differences between sterilizer for palm oil mill and cooking for vegetable oil.

1, Different raw material: the raw material of sterilizer for palm oil: palm fruit and palm fruit bunches, while, the raw material for vegetable oil cooker: peanut, sesame, etc.

2, Different functions:

The sterilizer for palm oil mill is to prevent enzymes broken down, avoiding FFA content in oil further increase, at the meanwhile, the temperature will make the fruits soften, it is easy for threshing, pretreatment peeling, prepared for the following-up process, like pressing, husking, it can reduce the damaged kernel.

The cooker for vegetable oil: the main function of cooker is wetting, heating, cooking and drying the raw material flakiness, the effectiveness of the cooking will affect on the oil out rate and the quality of the material.

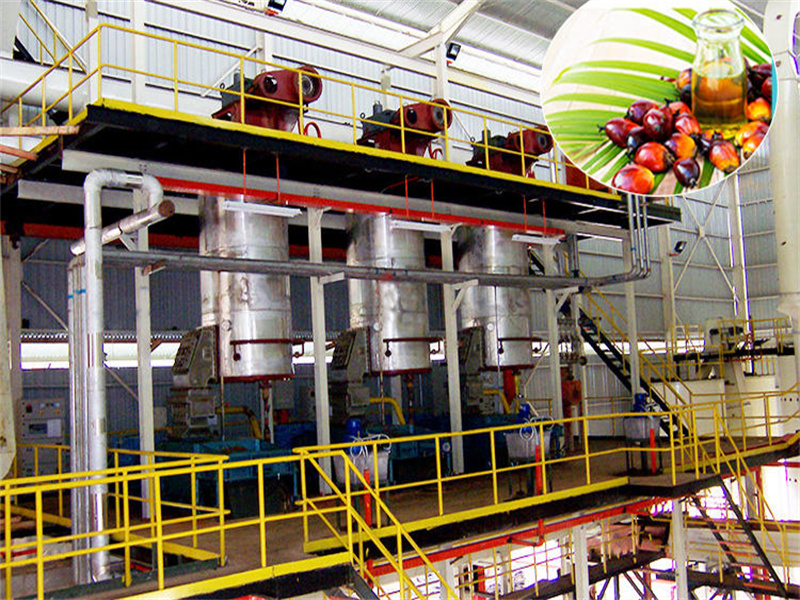

The main processes of the palm oil refinery include below steps: de-gumming and de-acidification step, de-colorization step, de-odorization step, and cooling and filtering step.

And there are three types of palm oil refinery plant process: batch type palm oil refinery plant, semi-continuous palm oil refinery plant and the continuous palm oil refinery plant.

As for the batch type palm oil refinery plant, we have below capacity: 1t/day, 2t/day, 3t/day, 5t/day and 10t/day.

The semi-continuous palm oil refinery plant, we have the below capacity: 10t/day, 20t/day, 30t/day, and 50t/day.

Continuous palm oil refinery plant have below capacity: 50t/day, 60t/day, 70t/day, 100t/day, 120t/day, 150t/day, 200t/day,300t/day and etc.

The advantages of each palm oil refinery plant:

1) The price of the batch type is cheapest among all of them. The continuous oil refinery is most experience. The semi-continous way is middle cost.

2) The oil yield rate of the continuous oil refinery is higher than the batch and semi-continuous oil refinery, because the connecting time of oil and lye is shorter.

3) The nigre of the continuous way contains lower oil, because the function of centrifugal.

4) The lye dosing system can reduce the oil consumption in continuous oil refinery.

5) The size is smaller of continuous way than the batch and semi-continuous way, because the refining and degumming tanks need more space.

6) The white clay dosing system and decolorization tower are used in the continuous oil decolorization section. It can keep the stabilized quality of final oil .

Packaging & Shipping

Each cooking oil machine is well packed by thin films.

Use iron case or iron pallet to fix the machine strongly.

All goods are ensured to arrive on time based on sales order requirements.

Our Services

1. Professional solution design, high quality machines, competitive prie.

2. Consult and answer all your questions within 24 hours.

3. Factory layout design according to your requirement.

4. Formulation available.

5. Fast delivery:15 working days for single machine/40 working days for complete line

6. Professional engineer, overseas installation and commissioning, training.

7. Warranty: 1 years

8. Service life long technical support.

Save

Technical parameters of Palm Oil Making Machine Palm Oil Processing Machine in Cameroon

| Voltage | 220V/380V/440V |

| Power(W) | According to the capacity |

| Dimension(L*W*H) | According to the capacity |

| Weight | According to the capacity |

| Certification | CE ISO |

| After-sales Service Provided | Engineers available to service Machine overseas |

| Item | Palm Kernel/Cotton Seeds Oil Extraction Plant Equipment |

| Warranty | 12 Months |

| Feature | High output |

| Performance | Perfect |

| Application | Oil Production Line |

| Manufacturing experience | Edible Oil Field |

| Advantage | Professional engineer team in oil extraction plant design |

| Capacity | 10--3000TPD |

| Type of extractor | Rotocel extractor, Loop type extractor,Chain Extractor, |

| Main market | Asia, Europe, Africa, South Ameriaca, |