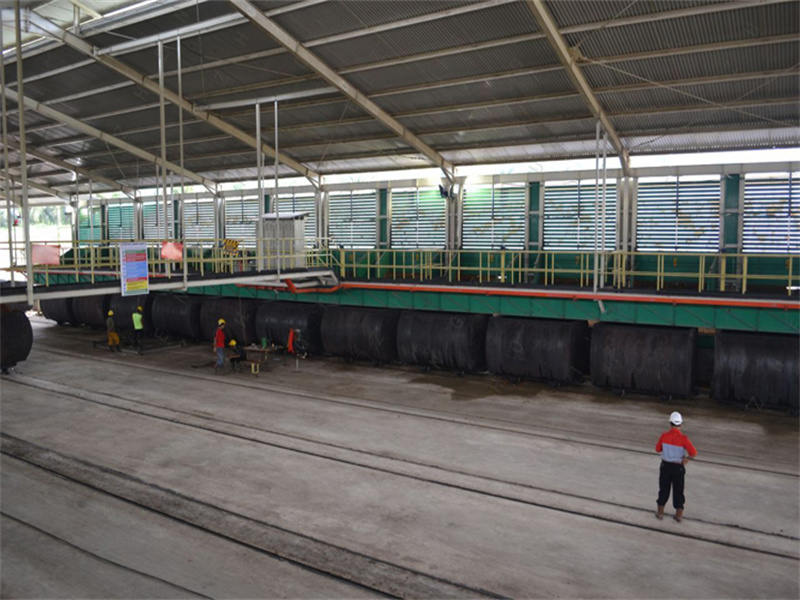

Palm Oil Production Line Machineing Machine Palm Oil Milling Machine in Cape Town

- Usage: oil press

- Type: Other

- Automatic Grade: Automatic

- Production Capacity: 2T--80T per hour

- Model Number: palm oil machine

Palm Oil Production Line Machineing Machine Palm Oil Milling Machine in Cape Town Description

small scale palm oil refining Machine

1.We are Alibaba Assessed 7 years Gold Supplier.

2.We are a factory manufacturing edible oil machine from 1982,best production capability,best quality control, Best Service.

3.Inspected by the Inspection Institution of Bureau Veritas Certification.

4.100% QC inspection Before Shippment.

5. CE listed,competitve price.

small scale palm oil refining Machine- Characteristics

The refining unit is intermittent, which has all the features of large and medium-sized intermittent refining device .It is better than the large and medium-sized refinery equipment.

The complete unit combination is selfheat, electrical control, light weight, low power consumption. Customers only need to use power and water (2meterhigh water tank too) and to prepare a little coal or wood, caustic soda, phosphoric acid and carclazyte and other materials to consumer.

This unit is no special plant, no special foundation, indoor and outdoor can be used.

small scale palm oil refining Machine–main equipments

1.Neutralization pot: for acid refining, alkali refining and washing;

2.Decoloration pot: for bleaching oils and removing pigment

3.Deodorization pot: for removing oil stink; (stainless steel)

4.Heatconducting oil furnace: Provide bleaching, deodorizing required vacuum can reach 755mmHg or more;

5.Air compressor: dry bleaching carclazyte

6.Filter press: filtering carclazyte

7.Steam generator: generate the required steam distillation deodorization.

small scale palm oil refining Machine-flowchart

Crude oil → 2. Degumming → 3. Bleaching → 4. Deacidfication → 5. Frame filter → 6. Deodorization

→ 7. Dewaxing → 8. Leaf filter

1.Decolour tank is for bleaching grease.

2.Deodorizing tank is for desdorizing grease(stainless steel).

3.Conducting oil furnace provide thermal enery need for production, the temperature reach to 280degree.

4.Vacuum pump provides vacuum for bleaching, deodorization which can reach 755mmHg or more;

small scale palm oil refining Machine- Working process:

(1)Pump crude oil into refining tank and heat with conduction oil, and the temperature will reach about 70°C 80C after one hour. Add acid or alkali to separate according to the acid value. After one hour’s processing and 4-6 hours deposit, then convey soap stock to storage tank.

(2)Pump refined oil into decoloring tank. When it is up to 90-110°c after one hour’s heating,add clay into tank for 20min’s processing. Then separate clay and oil with filter.

(3)Put discolored oil into deodorization tank with vacuum pump. Heat and process with steam for odor removal.After filtering, you will get final oil product.

small scale palm oil refining Machine

CertificationsFAQ

1. Q: Which kind of materials can be processed?

A: All kinds of oil seeds. For example, rice bran, corn germ, cottonseeds, peanut, sunflower, soybean, rapeseed, etc.

2. Q: What’s the capacity?

A: 5-2000 tons per day.

3. Q: The materials of our machine?

A: The stainless steel and carbon steel.

4. Q: Can you install the machine in local place.

A: We will send our engineers to local place to help installing the machine.

5. Q: How to operate the machines?

A: Our engineers will train the worker how to operate it after running.

Contact

If you have interest in small scale palm oil refining Machine,please kindly send us your inquiry details in the Below , Click “Send” Now!

Technical parameters of Palm Oil Production Line Machineing Machine Palm Oil Milling Machine in Cape Town

| Voltage | 220V/380V |

| Power(W) | Accoding to your capacity |

| Dimension(L*W*H) | Accoding to your capacity |

| Weight | Accoding to your capacity |

| Certification | ISO9001 |

| After-sales Service Provided | Engineers available to service Machine overseas |

| Item | palm oil milling machine |

| Capacity | 2T/H-80T/H |

| Product name | CPO |

| Function | To produce CPO |

| Advantage | advanced technology, many project experiene |

| what can we do | turn key, mechanical, civil, electrical, boiler |

| installation period | 6--8month |

| engineer | send engineer to site |

| Warranty | after commissioning all ok and long time technical support |

| Manufacturing experience | 35 years |