Singapore Wilmar Partner 100Tpd Palm Kernel Expeller Malaysia

- Usage: mini crude palm oil refine

- Type: mini crude palm oil refine

- Automatic Grade: Automatic

- Production Capacity: 50-500TPD, 10-300TPD oil refining machine

- Model Number: PL-67

Singapore Wilmar Partner 100Tpd Palm Kernel Expeller Malaysia Description

Specifications

Processing of Crude Palm Oil

1.low cosumptions

2.professional technology

3.good perfermance

4.turn-key plant

2014 Patent technology Processing of Crude Palm Oil

Tel:+86 15237168511

Processing of crude palm oil:

The specification of crude palm oil

|

Item |

Standard |

|

Smell and taste |

The original smell and taste of palm oil |

|

Moisture and volatile matter (%) ≤ |

0.20 |

|

Insoluble impurities (%) ≤ |

0.20 |

|

Acid value (mgKOH/g) ≤ |

4.0 |

|

Peroxide value (mmol/kg) ≤ |

7.5 |

Processing of crude palm oil:

1. Raw materials storage section: Fresh palm fruit bunch must be first measurement recorded by the pound into the plant, then unloaded to loaded fruit slopes and stored.

2. Sterilizing section: fresh palm fruit bunch are airtight sterilized in sterilizer. The purpose to prevent enzymes broken down.

3. Threshing section: The purpose of threshing is the oil palm fruit be separated from the fruit bunch.

4. Pressing section: To get the crude palm oil from the palm fruit.

5. Clarification section: Machine-pressed crude oil first diluted with water washing, through settlement and filtration, the fiber material removed from the oil, and then carry out continuous settlement, the whole divided into two parts: oil and sediment. 6. Finished oil storage and transportation section: To store the finished oil.

7. Fiber separation section: Press cake broken by breaking screw conveyor and then transported into the fiber separation air net for fiber separating. 8. Kernel recovery section: Separating the kernel from the palm meal.

9. Sewage treatment section: If there is high requirement of the waste water, we need this section to treat the waste water.

Reception station: Palm fruit oil mill Reception is used for loading the Fresh fruit bunch (FFB) to the palm fruit cage. Adopt hydraulic control system. as our experience, some palm oil pant use concrete structure, but it’s not good for cleaning. Now we adopt steel material, fence structure. Some impurity will drop down to a conveyor, impurity will conveyed to outside. Easy for cleaning. Low cost, Simple structure, Easy operated.

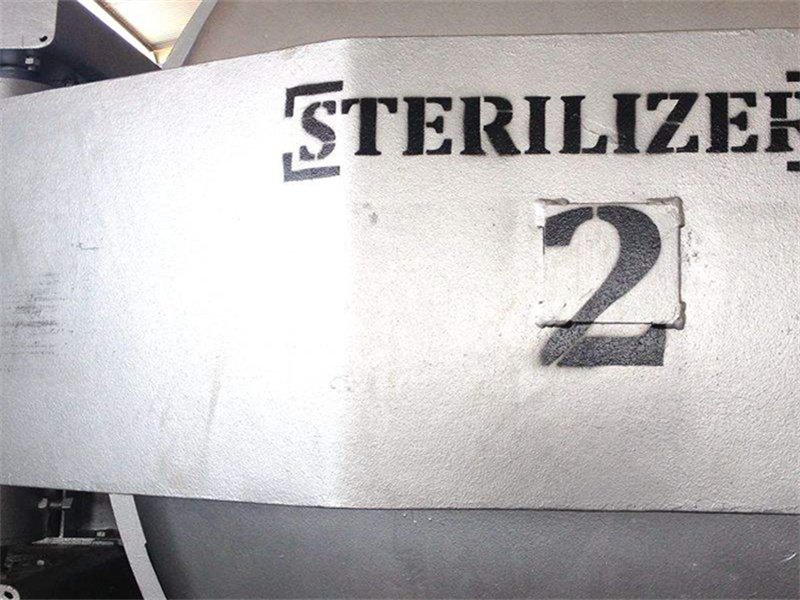

Palm oil plant sterilizing station.

For big scale palm oil mill, we adopt horizontal sterilizer, can produce continued increase the effective. Sterilizing station adopt high quality material, have characteristics of long time life , Low failure rate, easy maintain, etc.

Sterilizer can be design as owner’s requirement, Besides the horizontal sterilizer we also can supply vertical sterilizer for our customer.

As the sterilizer in palm oil plant belong pressure vessel, we have special certification from Government of the People’s Republic of China. Can supply good quality products and offer complete after-sales service, include engineer abroad service.

Thresher:Palm fruit thresher in palm oil plant is used for separate empty fruit bunch and palm fruit.

According the palm oil mill capacity we can design the thresher capacity, usually we have a spare one, in case one of them not work. Empty fruit bunch from thresher will be conveyed to outside, can be used as fertilizer in palm fruit plantation. Sterilized palm fruit will be convey to next station.

In the threshing station, we adopt stell structure, easy clean, easy operate, easy maintain.

Pressing station:Pressing station in palm oil plant is include digestor and oil presser.

Sterilized palm fruit from thresher conveyed to digestor. There are blades in digestor, blades will be rolling by motor which is on the top of digestor. Palm fruit peel can be crushed by blades, besides we will fill the steam in digestor for heating. Palm fruit pulp cell can be destroyed under the high temperature condition, after that we can get higher oil yield.

Screening filter: Remove the impurity in the oil

Decanter Centrifuge :Clarification in the palm oil station. For crude oil clean, we use screening filter and Decanter Centrifuge to remove the impurity in the crude oil. After process the impurity in the oil can get storage standard.

Our customers from all over the world

Welcome to visit our web:

Technical parameters of Singapore Wilmar Partner 100Tpd Palm Kernel Expeller Malaysia

| Voltage | 380-440V |

| Power(W) | according the capacity of refining |

| Dimension(L*W*H) | according the capacity of refining |

| Weight | Different |

| Certification | BV and CE certification |

| After-sales Service Provided | Engineers available to service Machine overseas |

| Phosphoric acid | 2~3 kg/T oil |

| Waste bleaching earth oil content | 25% to 35 % |

| soften water | 150Kg/T oil |

| Refining rate | refining consumption 1% |

| Bleaching earth consumption | 3-5Kg/Toil |

| Circulating water cooling water yield | 150M3/H |

| Steam consumption | 450kg/T oil |