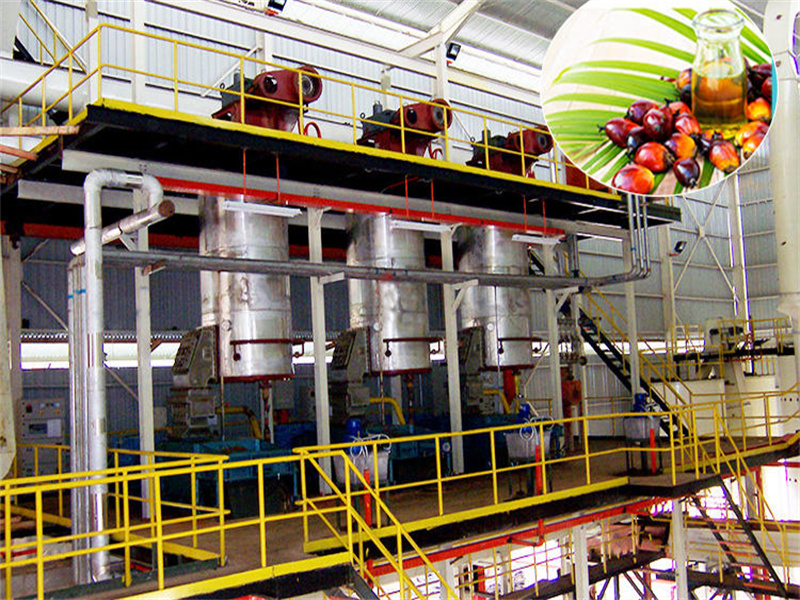

The Newest Technology Palm Oil Screw Press in Nigeria

- Usage: Palm Oil

- Type: whole palm fruit oil press

- Automatic Grade: Automatic

- Production Capacity: 100%

- Model Number: 1st series Doing palm fruit oil press

The Newest Technology Palm Oil Screw Press in Nigeria Description

crude palm oil processing Machine | red palm oil making Machine

From fresh fruit bunches to crude palm oil, following is a brief introduction of crude palm oil processing by QIE Machinery . QIE supply all kinds of palm oil machines.

- Raw materials reception and storage

Workers pick fresh fruit bunches (FFB) , transport them to factory with cars, get the weight by Loadometer and discharge them to material platform which is specially designed for crude palm oil processing, laying up for latter process. Open the gate of discharging platform, FFB would fall down to the conveyor automatically and be sent to sterilizing section.

Sterilizing section

The function of sterilizing, known as stewing in high temperature, is to avoid the deterioration of fruit. This section can avoid the increase of palm oil AV by stewing the fruit about 60min with 300kPa steam in a specialized sterilizer.

Threshing section

The palm fruit proportion is about 60% of the FFB. In this section, we always use rotating drum thresher to separate palm fruit from the bunches.

Crashing The purpose of crushing is to destroy palm skin, separate the palm pulp and nuts, pound palm pulp and to damage the cell structure of palm pulp by heating at the same time, which avail the latter pressing section.

Separate the fiber from the mixture derived from pressing by subsidence and filtration, after continuous subsidence we can separate oil and precipitate. With another filtration and vacuum drying, the oil is just crude palm oil as we say.

This is just a brief introduction of crude palm oil processing, and there’s still many details in crude palm oil processing. If u have any questions about crude palm oil processing, please contact me.

4 . Advantages

(1) High oil yield , obvious economic benefit .

(2) Residual oil rate in the dry meal .

(3) Improving the quality of the meal .

(4) Low processing cost , high labor productivity.

4.

Professional Advice

Please kindly inform us your required daily capacity, treated quantity, raw material, covering space and related data,so that we can make flow chart production line for you as your requirement. we will stand at your point to suggest low cost and suitable production line for you. Sincerely want to cooperate with you.

Besides extraction equipment, our company also provide high quality prepressing equipment and refining equipment with which you can prepress the raw material and refine the crude oil for different standards.

Welcome to contact us.

Technical parameters of The Newest Technology Palm Oil Screw Press in Nigeria

| Voltage | 380V |

| Power(W) | according to capacity |

| Dimension(L*W*H) | various with capacity |

| Weight | changed with capacity |

| Certification | CE and ISO |

| After-sales Service Provided | Engineers available to service Machine overseas |

| Raw material | palm |

| Product | to make crude palm oil or refined palm oil |

| Solvent name | n-hexane |

| Capacity | from 5T to 2000T palm fruit oil press |

| Oil content in peanut | about 40% |

| Oil residues | less than 1% |

| Function | getting palm oil |

| Manufacturing experience | 19 years experience in edible oil field |

| Warranty | 12 months |

| Material of equipment | stainless steel and carbon steel |