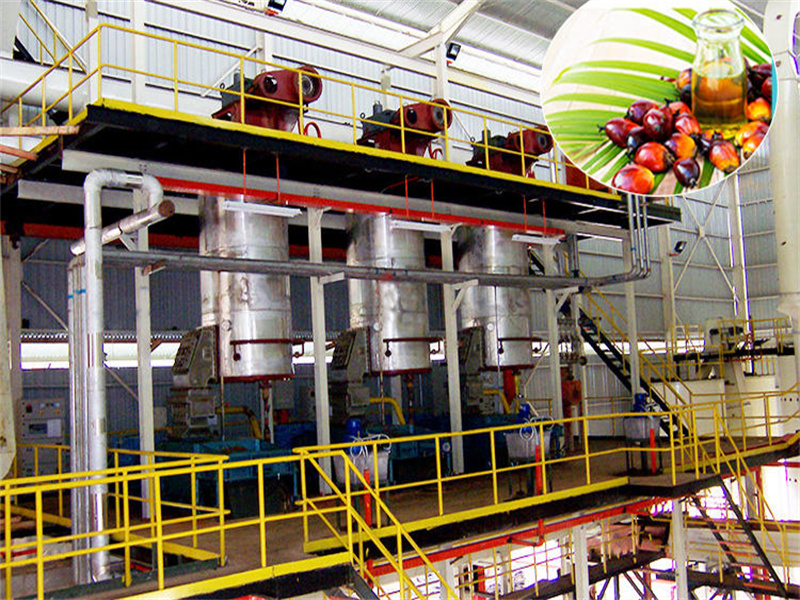

Best Selling Palm Kernel Oil Pressing Equipment in Papua New Guinea

- Usage: Palm Oil

- Type: Palm oil mill plant, Continuous

- Automatic Grade: Automatic

- Production Capacity: 1T/H & 2T/H

- Model Number: JL061

Best Selling Palm Kernel Oil Pressing Equipment in Papua New Guinea Description

Jinxin Best selling palm kernel oil pressing equipment

Applicable oil plants

Many oil plants, such as rapeseeds, cotton seeds, soybean, shelled groundnut, flax seeds, sunflower seeds and palm kernel, etc, especially for making refined high class plant oil.

This palm kernel oil mill is mainly used to press oils from oil bearing plants, with the characteristics of high quality, cheap price, compact structure and good after sale service.

1. Pretreatment of Palm Kernel Oil Extraction Machine

A,The pretreatment refers to the process from oil seed with all kinds of impurities to oil extraction, it includes cleaning,shelling,cracking,conditioning,flaking and cooking.

B.The pretreatment is a very important section,it will directly affect the oil making effect. C,The pretreatment machines as follows.

2. Palm Kernel Oil Extraction Machine A, The leaching process refers to use a kind of solvent that can dissolve the oil ,through humidify the oil and molecular diffusion,then extract the oil from the castor seed flake. B, The castor oil leaching process flow chart and the castor oil leaching machines as follows.

3.Refining Processing of Palm Oil Mill Machine lA,the first step is degum,add the phosphoric acid to the crude oil,the weight is 1‰of the oil’s,the concentration is 85%.stir for 5 minutes then add hot water 80°C, weight is 4%of the oil.after stilling 120 minutes, let off the residue.

lB,the second step is deacidify,as the castor oleic value is generally less than 6, so have to use a high concentration of lye.adding the lye into the oil(about 80°C)quickly,then stir,the still about 4 to 5 hours.at last let off the soapstock.

lC, the third step is washing,heat the oil about 85°C,then add the same hot water that weigh 20% of oil ,then stir, still about 40 minutes is ok, generally washing 2 times.

lD,the forth step is dry decoloring,The drying temperature is 105 ° C to 110 ° C, vacuum 0.08Mpa to 0.094Mpa is a dry qualification.use the dry acid clay, activated carbon, and bleaching temperature is100 -110 ° C, vacuum reach 0.08Mpa ~ 0.094Mpa.at last filtrate after cooled to 70-80°C,then will get the refined castor oil. lE,the castor oil refining process flow chart and refining machines as follows.

The degumming machine

The deacidify machine

Our Workshop of Plant

Packaging site

Technical parameters of Best Selling Palm Kernel Oil Pressing Equipment in Papua New Guinea

| Voltage | 380V/410V 3 phase |

| Power(W) | 30KW |

| Dimension(L*W*H) | 26000*2000*1500 |

| Weight | 15tons |

| Certification | CE and ISO |

| After-sales Service Provided | Engineers available to service Machine overseas |

| Supplier type | Manufacturer |

| Function | make palm oil |

| Texture | Mild steel and SS |

| Raw material | Palm fruits |

| Handling capacity | 1t/h,2t/h,5t/h,10t/h,15t/h,2ot/h |

| Warranty | 1 year |

| Production cycle | 40days |

| Installation period | 60 days |

| Shipping terms | FOB Qingdao or Tianjin |