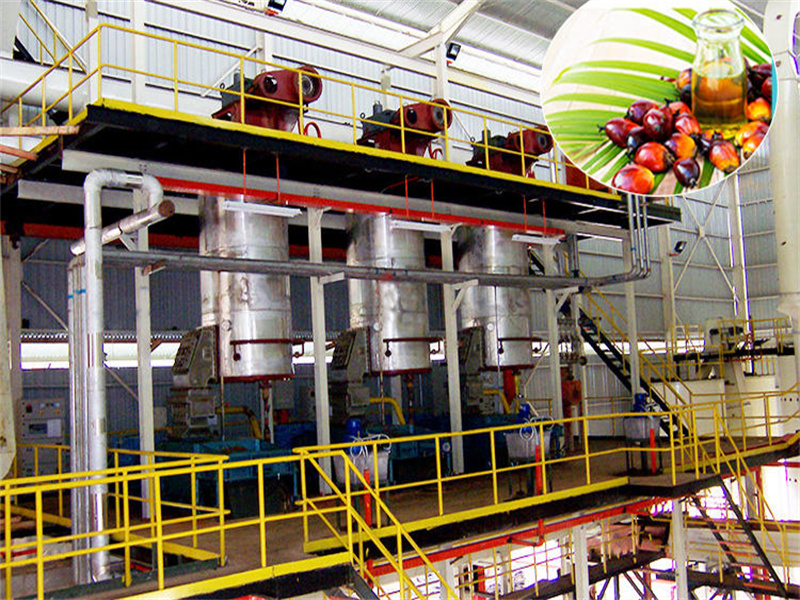

Qie 60Tpd-2000Tpd Palm Thresher in Papua New Guinea

- Usage: Palm Oil

- Type: palm oil mill design

- Automatic Grade: Automatic

- Production Capacity: 10-3000TPD

- Model Number: QIE133

Qie 60Tpd-2000Tpd Palm Thresher in Papua New Guinea Description

QIE 10TPD-2000TPD palm oil distillation machine QIE 10TPD-2000TPD palm oil distillation machine

palm oil processing

1, palm oil distillation machine fractionation process introduction Palm oil fractionation and degrease process work under slowly stirring and cool the oil to certain temperature in fixed time (technical security), and make waxy formed bigger crystallization, then separation exhalation, after filtering, it separates the fluid oil and solid fat. After fractionation, the oil will be clean after 5.5 hours in 0 ℃, but it also can keep the transparency and flowability in the refrigerator and improve the oil quality and appearance. 2, palm oil distillation machine main procedures

1, Crystallization

2, Filtering

3, Part of palm oil fractionation plant

3, Some datas

Crude palm oil standard:

| FFA | less than 5% |

| Moisture | less than 0.1% |

| Dirt | less than 0.02% |

Kernel standard:

| Broken kernel | less than 15% |

| Moisture | less than 7% |

| Dirt | less than 6% |

Production quality index:

1,transparency : clear and transparent.

2,smell and taste: no strange smell;

3,color (lovibond colorimeter 133.4 slots) ≤ R1Y10;

4,moisture and volatile matter: ≤ 0.10%;

5,impurities content : ≤ 0.10%;

6,acid value (mgKOH/g) : ≤ 0.12;

7,peroxide value (mmol/kg): ≤ 3.

Company Information

Company Information

Our Strength

1, Established in 1982, we have more than 30 years experience. Our goal is to be pioneer in global grain and oil industry. 2, We have deep cooperation with Henan Machine Design Research Institute and Henan University of Technology. Our professor often go abroad attending grain and oil conference and forum. 3, We have completed service line including technical department, engineering department, project department,

electronic commerce department, domestic trade department and foreign trade department. After signing contract, we will set up special team including engineers, installation technicians, drawing designer, business person, after-sales service person, and so on. We will provide one-to-one service. Our Service

-

Whole set of equipment for production line.

-

Motor and power control system.

-

Installation material.

-

Installation and test-run.

-

Drawing of process description, equipment layout, foundation and hole, construction.

-

Drawing of power control.

-

Isolation and painting for equipment.

-

Water recycling and cooling system outside the plant (i.e. supplementary device).

-

Staff training and long-term technical service.

Main Business Field

- 10-500T/H oil material primary cleaning,drying and storage section turn-key project.

- 100-3000 T/D oil pretreatment, shelling and pre-press workshop turnkey project (soybean hot dehulling, bean skin crushing, the soybean extrusion, high oil contained pre-pressed cake extrusion and high oil contained flakes puffed directly). Rice bran turn-key project.

- 100-3000 T/D leaching workshop turnkey project (towline extractor, rotocel extractor, loop type extractor,

- DTDC separated machine, the full negative pressure evaporation,

- Paraffin wax recovery, leaching workshop degumming, phospholipid concentration).

- 30-1000T/D continuous physical (chemical) refining line.

- 20-3000T/D sunflower oil, rice bran oil, corn germ oil dewaxing turnkey project.

- 10-200T/D fatty acid esterification edible oil production line.

Our Installation Site Certificates

Our Certificates

Contact Information

Technical parameters of Qie 60Tpd-2000Tpd Palm Thresher in Papua New Guinea

| Voltage | 220V/380V |

| Power(W) | According to your Capacity |

| Dimension(L*W*H) | depend on the mode |

| Weight | depend on the mode |

| Certification | ISO9001 |

| After-sales Service Provided | Engineers available to service Machine overseas |

| Item | palm oil mill design |

| Water content in press cake | 40% |

| Oil extract rate | 21-23% |

| Oil content in press cake | 6 % |

| Oil content in final effluent | 0.6% |

| Kernel content in cyclone fiber | 0.15% |

| Kernel content in dry shell | 2% |

| Steel material | stainless |

| Market | Asia,Africa,Southeast Asia |